SERVICE HINT

Troubles with the power steering system are usually concerned with hard steering due to the fact that there is no assist. In such cases, before attempting to make repairs, it is necessary to determine whether the trouble lies with the pump or with the gear housing. To do this, an on-vehicle inspection can be made by using a pressure gauge.

ON-VEHICLE INSPECTION

Power steering is a hydraulic device and problems are normally due to insufficient fluid pressure acting on the piston. This could be caused by either the pump not producing the specified fluid pressure or the control valve in the gear housing not functioning properly so that the proper fluid pressure can not be obtained.

If the fault lies with the pump, the same symptoms will generally occur whether the steering wheel is turned fully to the right or left. On the other hand, if the fault lies with the control valve, there will generally be a difference between the amount of assist when the steering wheel is turned to the left or the right. For example, if the oil seal of the piston seal of the power cylinder is worn, there will be a loss of fluid pressure whether the steering wheel is turned to the right or left and the symptoms will be the same for both.

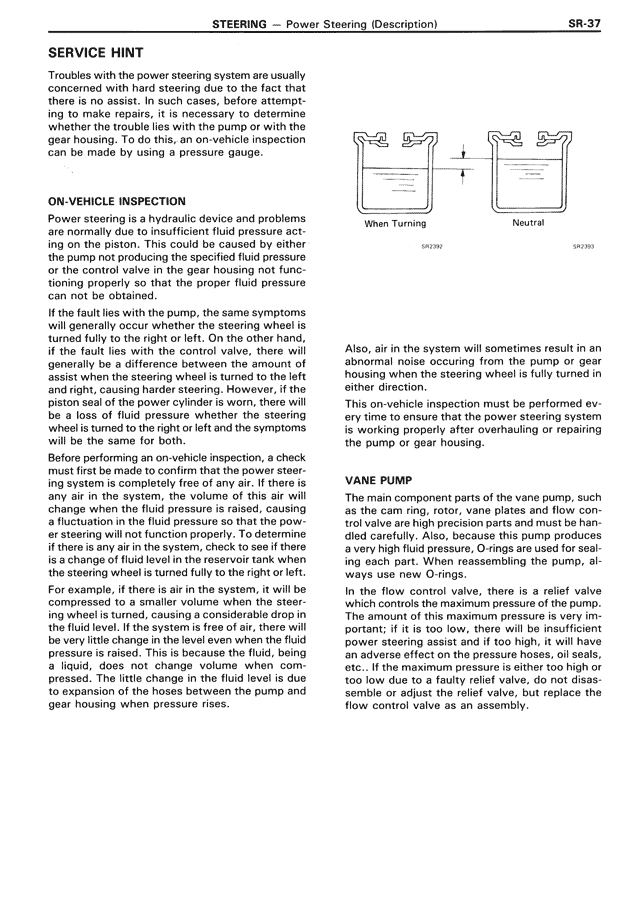

Before performing an on-vehicle inspection, a check must first be made to confirm that the power steering system is completely free of any air. If there is any air in the system, the volume of this air will change when the fluid pressure is raised, causing a fluctuation in the fluid pressure so that the power steering will not function properly. To determine if there is any air in the system, check to see if there is a change of fluid level in the reservoir tank when the steering wheel is turned fully to the right or left.

For example, if there is air in the system, it will be compressed to a smaller volume when the steering wheel is turned fully to the right or left, raising the fluid level. If the system is free of air, there will be very little change in the level even when the fluid pressure is raised. This is because the fluid, being a liquid, does not change volume when compressed. The little change in the fluid level is due to expansion of the hoses between the pump and gear housing when pressure rises.

[THIS IS FIGURE: Two diagrams showing fluid reservoir levels - one labeled "When Turning" showing higher fluid level, and one labeled "Neutral" showing normal fluid level]

Also, air in the system will sometimes result in an abnormal noise occuring from the pump or gear housing when the steering wheel is fully turned in either direction.

This on-vehicle inspection must be performed every time to ensure that the power steering system is working properly after overhauling or repairing the pump or gear housing.

VANE PUMP

The main component parts of the vane pump, such as the cam ring, rotor, vane plates and flow control valve are high precision parts and must be handled carefully. Also, because this pump produces a very high fluid pressure, O-rings are used for sealing each part. When reassembling the pump, always use new O-rings.

In the flow control valve, there is a relief valve which controls the maximum pressure of the pump. The amount of this maximum pressure is very important; if it is too low, there will be insufficient pump pressure developed. On the other hand, it has an adverse effect on the pressure hoses, oil seals, etc.. If the maximum pressure is either too high or too low due to a faulty relief valve, do not disassemble or adjust the relief valve, but replace the flow control valve as an assembly.