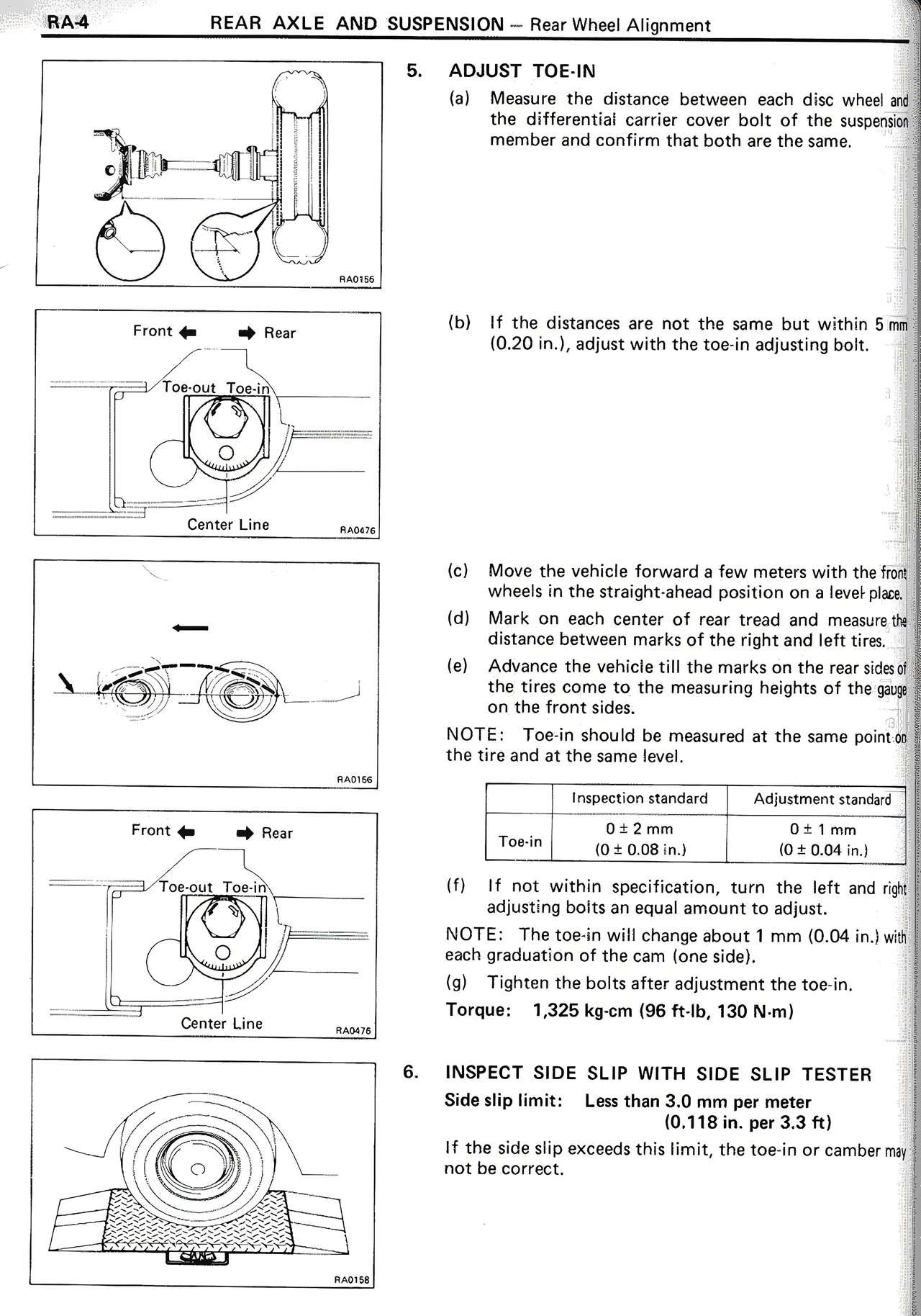

5. ADJUST TOE-IN

(a) Measure the distance between each disc wheel and the differential carrier cover bolt of the suspension member and confirm that both are the same.

(b) If the distances are not the same but within 5 mm (0.20 in.), adjust with the toe-in adjusting bolt.

(c) Move the vehicle forward a few meters with the front wheels in the straight-ahead position on a level place.

(d) Mark on each center of rear tread and measure the distance between marks of the right and left tires.

(e) Advance the vehicle till the marks on the rear sides of the tires come to the measuring heights of the gauge on the front sides.

NOTE: Toe-in should be measured at the same points on the tire and at the same level.

Inspection standard | Adjustment standard

Toe-in | 0 ± 2 mm (0 ± 0.08 in.) | 0 ± 1 mm (0 ± 0.04 in.)

(f) If not within specification, turn the left and right adjusting bolts an equal amount to adjust.

NOTE: The toe-in will change about 1 mm (0.04 in.) with each graduation of the cam (one side).

(g) Tighten the bolts after adjustment the toe-in.

Torque: 1,325 kg-cm (96 ft-lb, 130 N-m)

6. INSPECT SIDE SLIP WITH SIDE SLIP TESTER

Side slip limit: Less than 3.0 mm per meter (0.118 in. per 3.3 ft)

If the side slip exceeds this limit, the toe-in or camber may not be correct.