AUTOMATIC TRANSMISSION — Shift Lock System AT-143

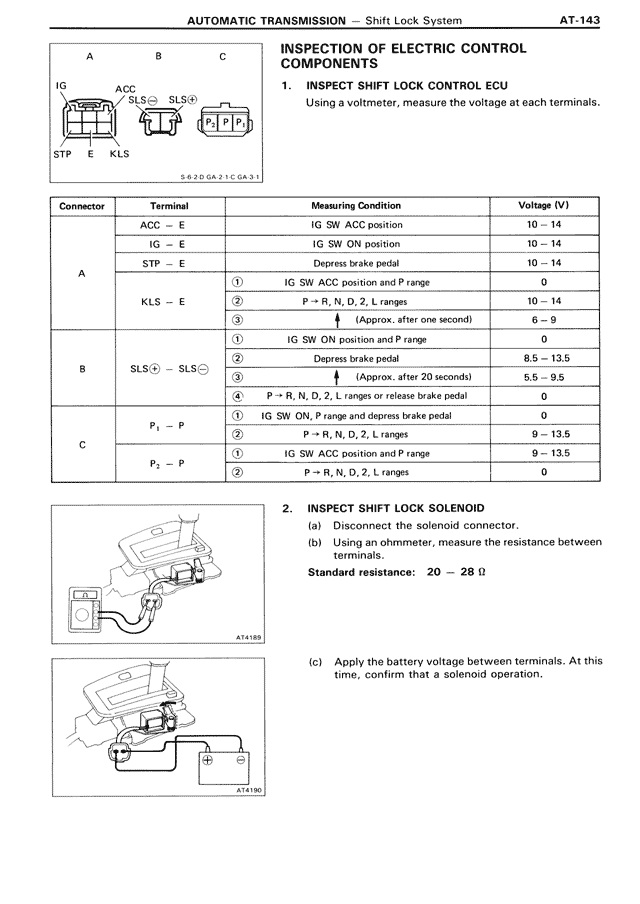

A B C

[Diagram showing connectors: IG, ACC, STP, E, KLS, SLS©, SLS①, P₁, P₂, P]

S.R.2-D GA 7 1C GA 3-1

INSPECTION OF ELECTRIC CONTROL COMPONENTS

1. INSPECT SHIFT LOCK CONTROL ECU

Using a voltmeter, measure the voltage at each terminals.

[THIS IS TABLE: Connector testing specifications with columns for Connector, Terminal, Measuring Condition, and Voltage (V)]

Connector | Terminal | Measuring Condition | Voltage (V)

A:

ACC — E | IG SW ACC position | 10 — 14

IG — E | IG SW ON position | 10 — 14

STP — E | Depress brake pedal | 10 — 14

① | IG SW ACC position and P range | 0

KLS — E | ② | P→R, N, D, 2, L ranges | 10 — 14

③ | ↓ (Approx. after one second) | 6 — 9

B:

① | IG SW ON position and P range | 0

SLS© — SLS① | ② | Depress brake pedal | 8.5 — 13.5

③ | ↓ (Approx. after 20 seconds) | 5.5 — 9.5

④ | P→R, N, D, 2, L ranges or release brake pedal | 0

C:

P₁ — P | ① | IG SW ON, P range and depress brake pedal | 0

② | P→R, N, D, 2, L ranges | 9 — 13.5

P₂ — P | ① | IG SW ACC position and P range | 9 — 13.5

② | P→R, N, D, 2, L ranges | 0

2. INSPECT SHIFT LOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Using an ohmmeter, measure the resistance between terminals.

Standard resistance: 20 — 28 Ω

[Diagram AT4189 showing ohmmeter testing]

(c) Apply the battery voltage between terminals. At this time, confirm that a solenoid operation.

[Diagram AT4190 showing battery connection test]