INSPECTION OF MASTER CYLINDER

HINT: Clean the disassembled parts with compressed air.

1. INSPECT MASTER CYLINDER BORE FOR SCORING OR CORROSION

If a problem is found, clean or replace the cylinder.

2. INSPECT PISTON AND CUPS FOR WEAR, SCORING, CRACKS OR SWELLING

If either one requires replacement, use the parts from the cylinder kit.

3. INSPECT PUSH ROD FOR WEAR OR DAMAGE

If necessary, replace the push rod.

ASSEMBLY OF MASTER CYLINDER

(See page CL-6)

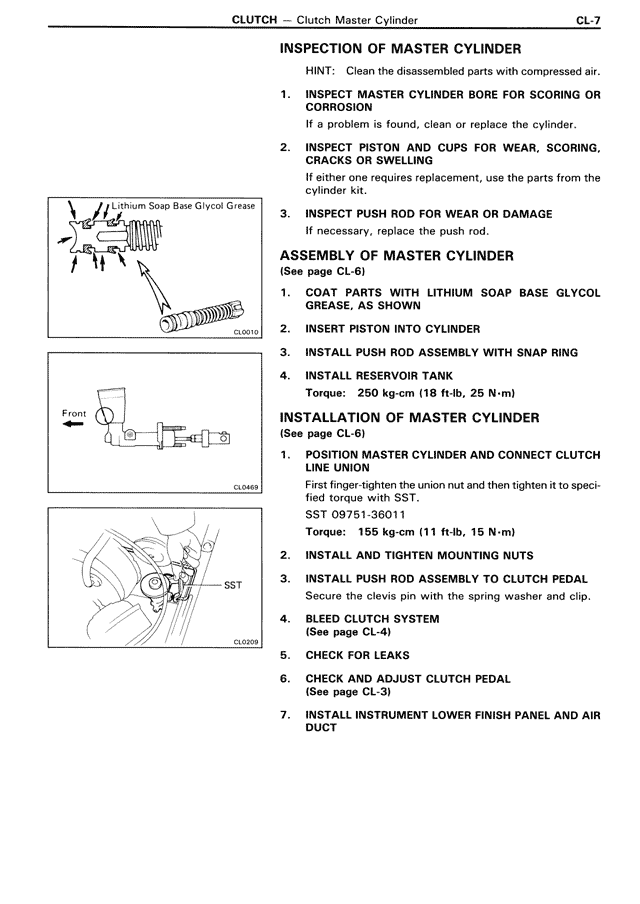

1. COAT PARTS WITH LITHIUM SOAP BASE GLYCOL GREASE, AS SHOWN

2. INSERT PISTON INTO CYLINDER

3. INSTALL PUSH ROD ASSEMBLY WITH SNAP RING

4. INSTALL RESERVOIR TANK

Torque: 250 kg-cm (18 ft-lb, 25 N-m)

INSTALLATION OF MASTER CYLINDER

(See page CL-6)

1. POSITION MASTER CYLINDER AND CONNECT CLUTCH LINE UNION

First finger-tighten the union nut and then tighten it to specified torque with SST.

SST 09751-36011

Torque: 155 kg-cm (11 ft-lb, 15 N-m)

2. INSTALL AND TIGHTEN MOUNTING NUTS

3. INSTALL PUSH ROD ASSEMBLY TO CLUTCH PEDAL

Secure the clevis pin with the spring washer and clip.

4. BLEED CLUTCH SYSTEM

(See page CL-4)

5. CHECK FOR LEAKS

6. CHECK AND ADJUST CLUTCH PEDAL

(See page CL-3)

7. INSTALL INSTRUMENT LOWER FINISH PANEL AND AIR DUCT