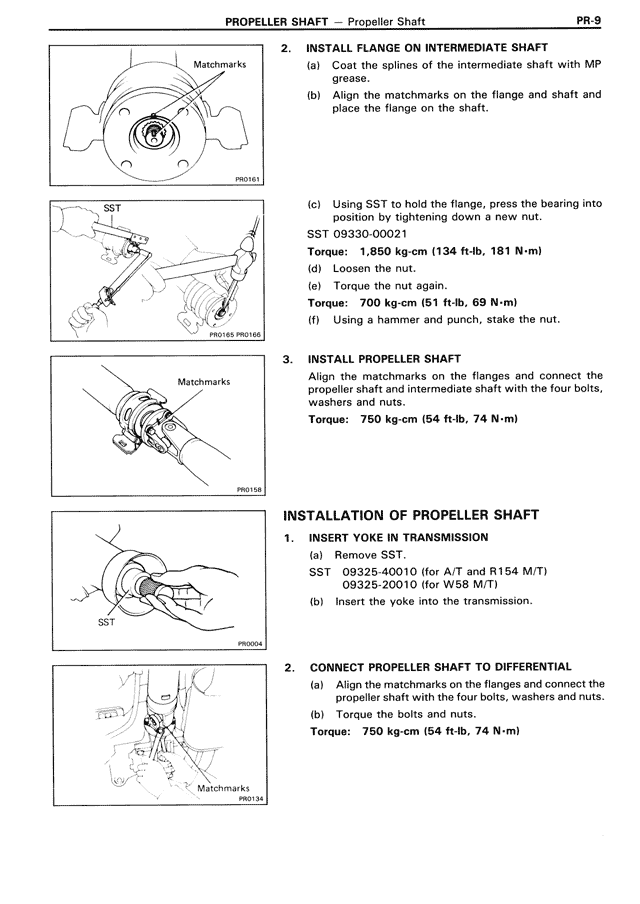

2. INSTALL FLANGE ON INTERMEDIATE SHAFT

(a) Coat the splines of the intermediate shaft with MP grease.

(b) Align the matchmarks on the flange and shaft and place the flange on the shaft.

(c) Using SST to hold the flange, press the bearing into position by tightening down a new nut.

SST 09330-00021

Torque: 1,850 kg-cm (134 ft-lb, 181 N-m)

(d) Loosen the nut.

(e) Torque the nut again.

Torque: 700 kg-cm (51 ft-lb, 69 N-m)

(f) Using a hammer and punch, stake the nut.

3. INSTALL PROPELLER SHAFT

Align the matchmarks on the flanges and connect the propeller shaft and intermediate shaft with the four bolts, washers and nuts.

Torque: 750 kg-cm (54 ft-lb, 74 N-m)

INSTALLATION OF PROPELLER SHAFT

1. INSERT YOKE IN TRANSMISSION

(a) Remove SST.

SST 09325-40010 (for A/T and R154 M/T)

09325-20010 (for W58 M/T)

(b) Insert the yoke into the transmission.

2. CONNECT PROPELLER SHAFT TO DIFFERENTIAL

(a) Align the matchmarks on the flanges and connect the propeller shaft with the four bolts, washers and nuts.

(b) Torque the bolts and nuts.

Torque: 750 kg-cm (54 ft-lb, 74 N-m)