CN-4 BODY PANEL CONSTRUCTION

RUST–RESISTANT SHEET STEEL PARTS

Rust–Resistant Sheet Steel have zinc, tin or aluminum etc, plating over the base metal surface in order to improve the corrosion resistance of the sheet metal. For the vehicle's body panels, galvannealed sheet steel is widely used.

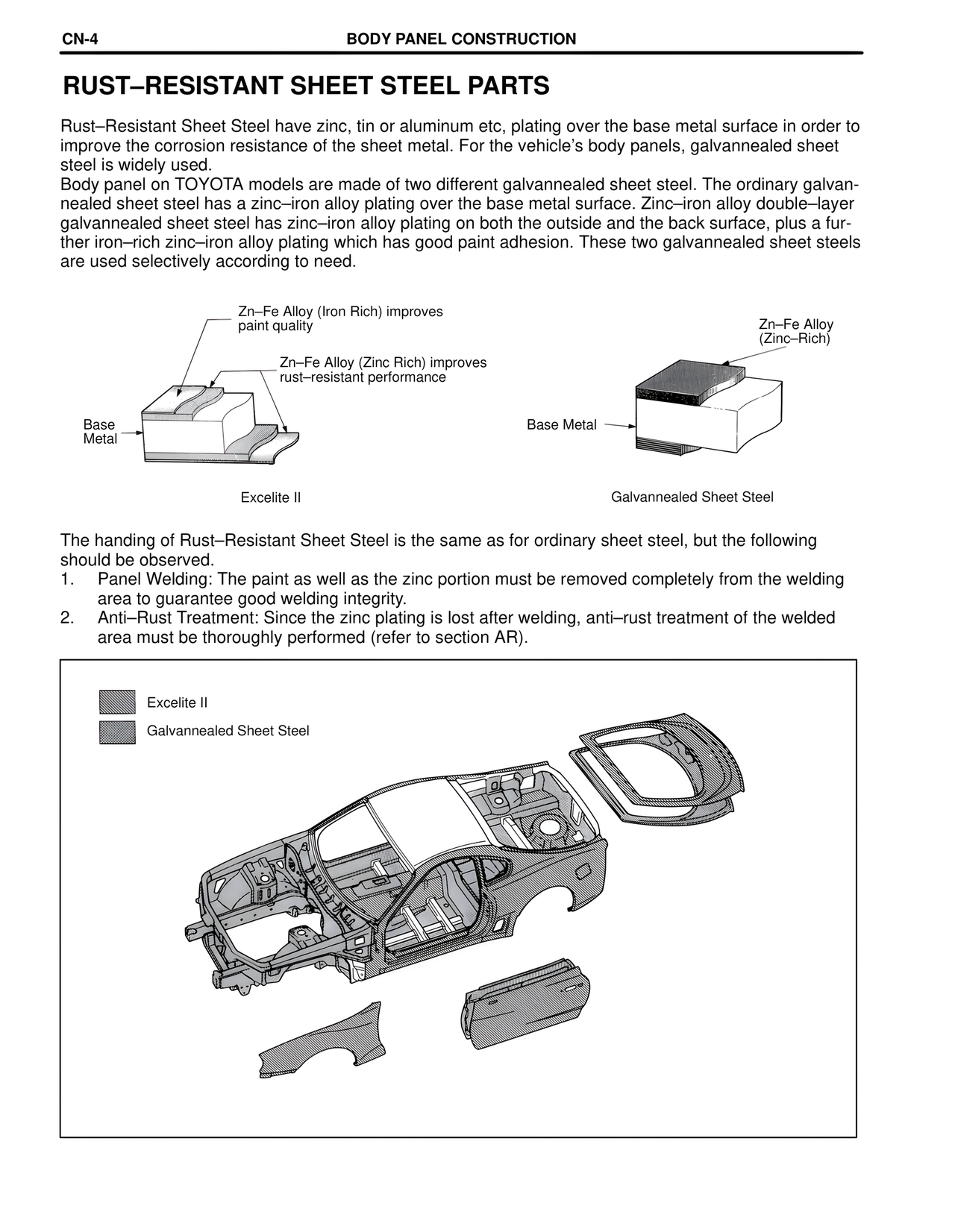

Body panel on TOYOTA models are made of two different galvannealed sheet steel. The ordinary galvannealed sheet steel has a zinc–iron alloy plating over the base metal surface. Zinc–iron alloy double–layer galvannealed sheet steel has zinc–iron alloy plating on both the outside and the back surface, plus a further iron–rich zinc–iron alloy plating which has good paint adhesion. These two galvannealed sheet steels are used selectively according to need.

Zn–Fe Alloy (Iron Rich) improves paint quality

Zn–Fe Alloy (Zinc Rich) improves rust–resistant performance

Base Metal

Excelite II

Zn–Fe Alloy (Zinc–Rich)

Base Metal

Galvannealed Sheet Steel

The handing of Rust–Resistant Sheet Steel is the same as for ordinary sheet steel, but the following should be observed.

1. Panel Welding: The paint as well as the zinc portion must be removed completely from the welding area to guarantee good welding integrity.

2. Anti–Rust Treatment: Since the zinc plating is lost after welding, anti–rust treatment of the welded area must be thoroughly performed (refer to section AR).

Excelite II

Galvannealed Sheet Steel