EG–169

ENGINE – EMISSION CONTROL SYSTEMS (2JZ–GE)

Disconnect

EGR Valve

To Intake Manifold

P11098

7. INSPECT EGR VALVE

(a) Apply vacuum directly to the EGR valve with the engine idling.

(b) Check that the engine runs rough or dies.

(c) Reconnect the vacuum hoses to their proper locations.

IF NO PROBLEM IS FOUND DURING THIS INSPECTION, SYSTEM IS NORMAL; OTHERWISE INSPECT EACH PART

VSV INSPECTION

(See VSV for EGR in SFI System)

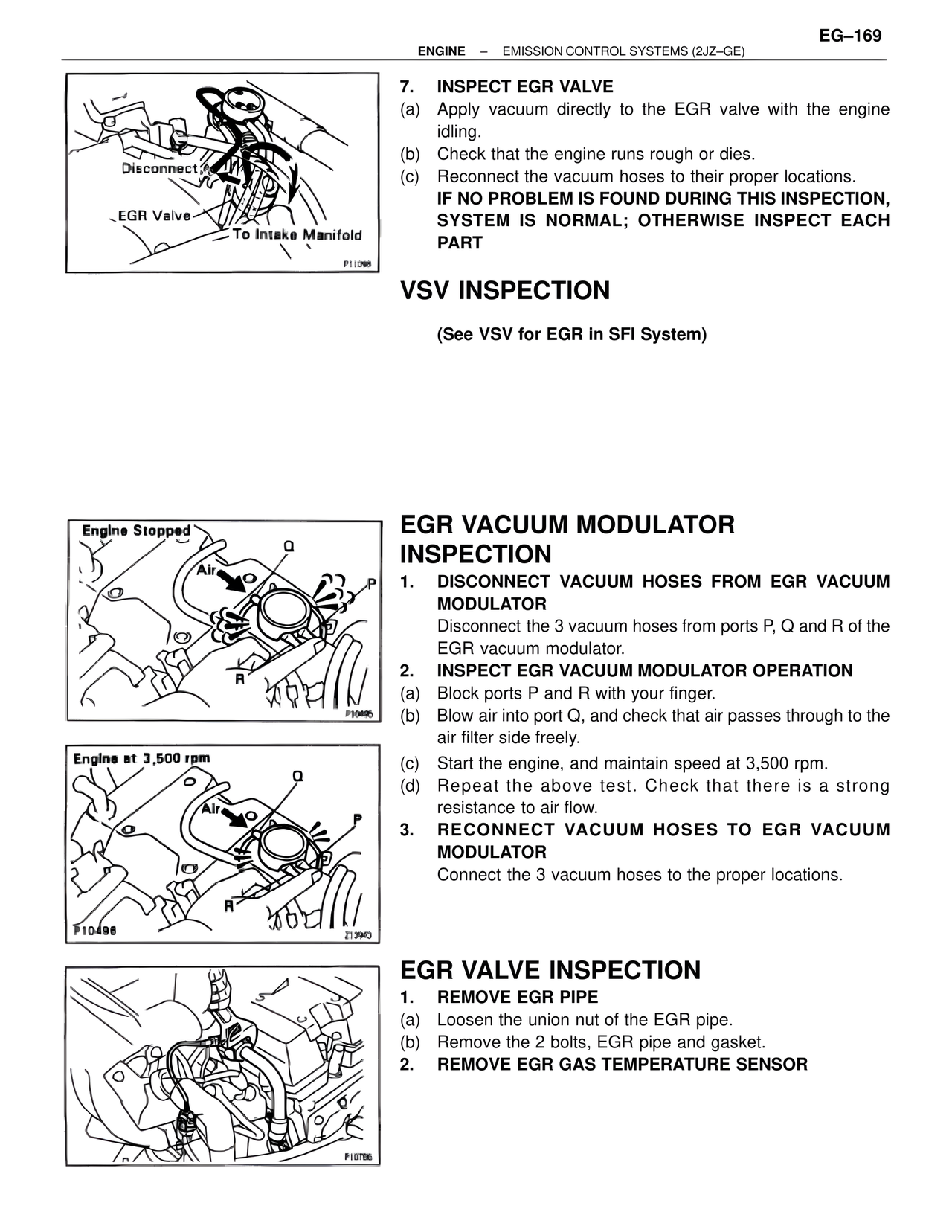

Engine Stopped

Q

Air

P

R

P10495

Engine at 3,500 rpm

Q

Air

P

R

P10498

Z13943

EGR VACUUM MODULATOR INSPECTION

1. DISCONNECT VACUUM HOSES FROM EGR VACUUM MODULATOR

Disconnect the 3 vacuum hoses from ports P, Q and R of the EGR vacuum modulator.

2. INSPECT EGR VACUUM MODULATOR OPERATION

(a) Block ports P and R with your finger.

(b) Blow air into port Q, and check that air passes through to the air filter side freely.

(c) Start the engine, and maintain speed at 3,500 rpm.

(d) Repeat the above test. Check that there is a strong resistance to air flow.

3. RECONNECT VACUUM HOSES TO EGR VACUUM MODULATOR

Connect the 3 vacuum hoses to the proper locations.

P10766

EGR VALVE INSPECTION

1. REMOVE EGR PIPE

(a) Loosen the union nut of the EGR pipe.

(b) Remove the 2 bolts, EGR pipe and gasket.

2. REMOVE EGR GAS TEMPERATURE SENSOR