EG–180

ENGINE – EMISSION CONTROL SYSTEMS (2JZ–GTE)

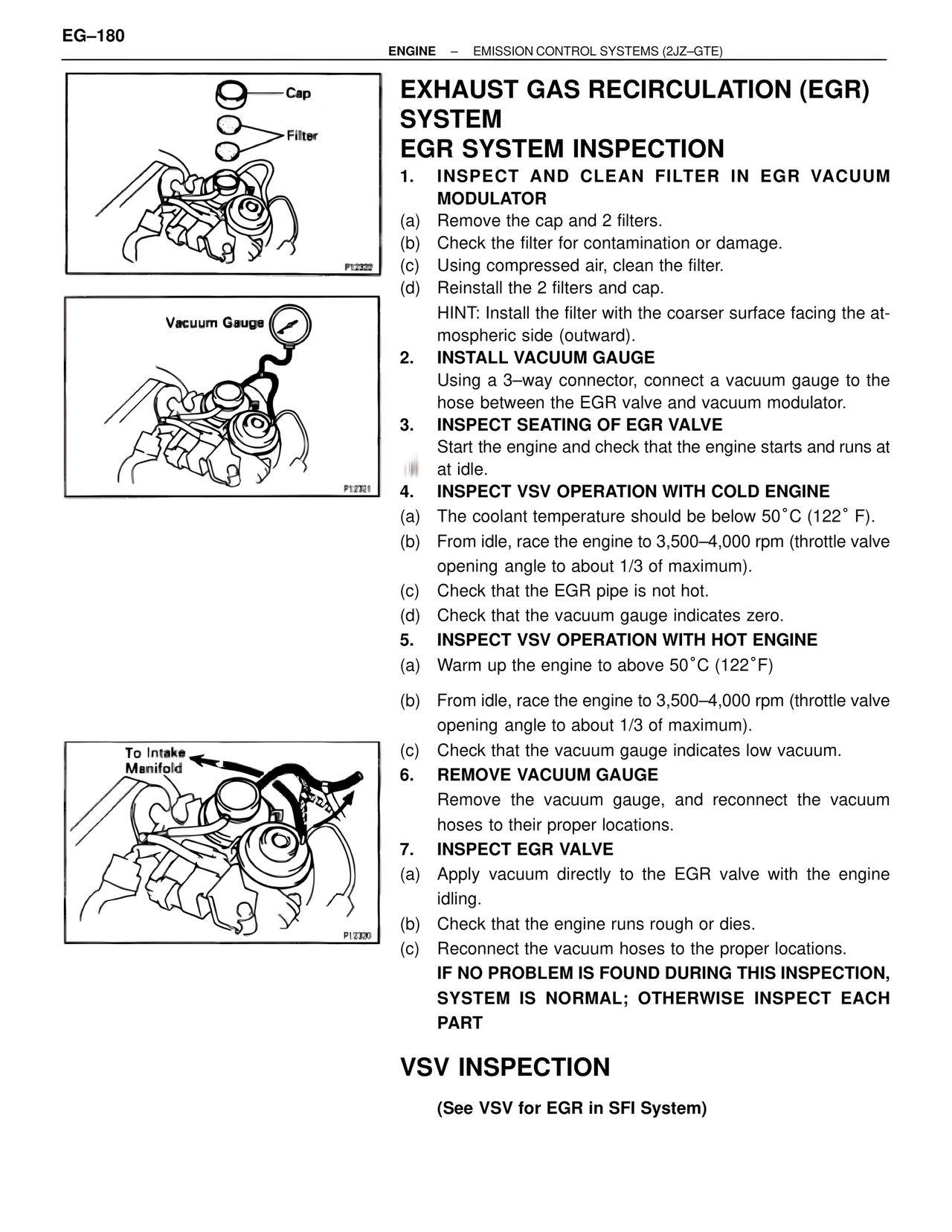

Cap

Filter

P12322

Vacuum Gauge

P12321

To Intake

Manifold

P12320

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

EGR SYSTEM INSPECTION

1. INSPECT AND CLEAN FILTER IN EGR VACUUM MODULATOR

(a) Remove the cap and 2 filters.

(b) Check the filter for contamination or damage.

(c) Using compressed air, clean the filter.

(d) Reinstall the 2 filters and cap.

HINT: Install the filter with the coarser surface facing the atmospheric side (outward).

2. INSTALL VACUUM GAUGE

Using a 3–way connector, connect a vacuum gauge to the hose between the EGR valve and vacuum modulator.

3. INSPECT SEATING OF EGR VALVE

Start the engine and check that the engine starts and runs at at idle.

4. INSPECT VSV OPERATION WITH COLD ENGINE

(a) The coolant temperature should be below 50°C (122° F).

(b) From idle, race the engine to 3,500–4,000 rpm (throttle valve opening angle to about 1/3 of maximum).

(c) Check that the EGR pipe is not hot.

(d) Check that the vacuum gauge indicates zero.

5. INSPECT VSV OPERATION WITH HOT ENGINE

(a) Warm up the engine to above 50°C (122°F)

(b) From idle, race the engine to 3,500–4,000 rpm (throttle valve opening angle to about 1/3 of maximum).

(c) Check that the vacuum gauge indicates low vacuum.

6. REMOVE VACUUM GAUGE

Remove the vacuum gauge, and reconnect the vacuum hoses to their proper locations.

7. INSPECT EGR VALVE

(a) Apply vacuum directly to the EGR valve with the engine idling.

(b) Check that the engine runs rough or dies.

(c) Reconnect the vacuum hoses to the proper locations.

IF NO PROBLEM IS FOUND DURING THIS INSPECTION, SYSTEM IS NORMAL; OTHERWISE INSPECT EACH PART

VSV INSPECTION

(See VSV for EGR in SFI System)