EG–100

ENGINE – ENGINE MECHANICAL

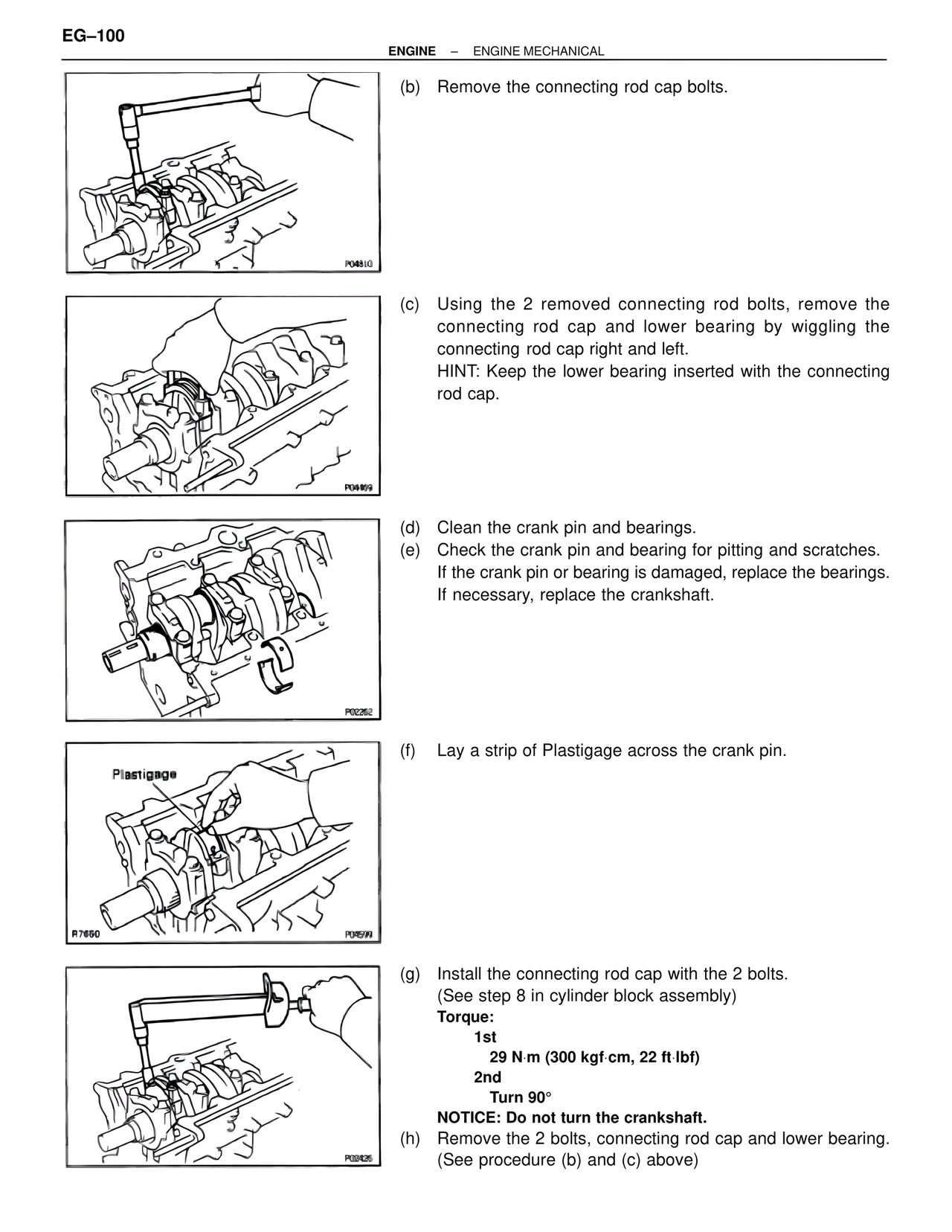

(b) Remove the connecting rod cap bolts.

P04810

(c) Using the 2 removed connecting rod bolts, remove the

connecting rod cap and lower bearing by wiggling the

connecting rod cap right and left.

HINT: Keep the lower bearing inserted with the connecting

rod cap.

P04499

(d) Clean the crank pin and bearings.

(e) Check the crank pin and bearing for pitting and scratches.

If the crank pin or bearing is damaged, replace the bearings.

If necessary, replace the crankshaft.

P02262

(f) Lay a strip of Plastigage across the crank pin.

Plastigage

R74660

P04599

(g) Install the connecting rod cap with the 2 bolts.

(See step 8 in cylinder block assembly)

Torque:

1st

29 N·m (300 kgf·cm, 22 ft·lbf)

2nd

Turn 90°

NOTICE: Do not turn the crankshaft.

(h) Remove the 2 bolts, connecting rod cap and lower bearing.

(See procedure (b) and (c) above)

P02426