ENGINE – ENGINE MECHANICAL

EG–111

3. INSPECT CONNECTING ROD

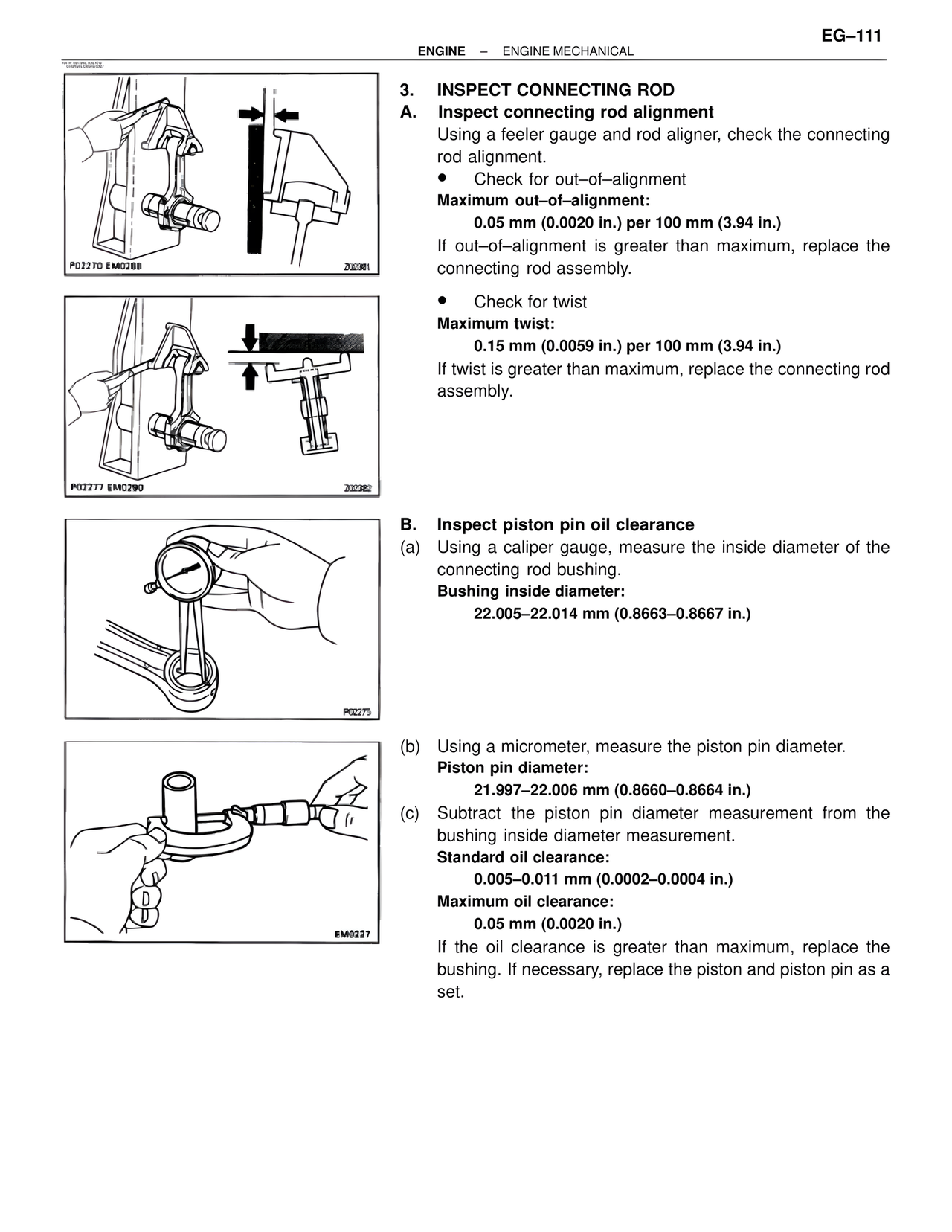

A. Inspect connecting rod alignment

Using a feeler gauge and rod aligner, check the connecting

rod alignment.

• Check for out–of–alignment

Maximum out–of–alignment:

0.05 mm (0.0020 in.) per 100 mm (3.94 in.)

If out–of–alignment is greater than maximum, replace the

connecting rod assembly.

• Check for twist

Maximum twist:

0.15 mm (0.0059 in.) per 100 mm (3.94 in.)

If twist is greater than maximum, replace the connecting rod

assembly.

B. Inspect piston pin oil clearance

(a) Using a caliper gauge, measure the inside diameter of the

connecting rod bushing.

Bushing inside diameter:

22.005–22.014 mm (0.8663–0.8667 in.)

(b) Using a micrometer, measure the piston pin diameter.

Piston pin diameter:

21.997–22.006 mm (0.8660–0.8664 in.)

(c) Subtract the piston pin diameter measurement from the

bushing inside diameter measurement.

Standard oil clearance:

0.005–0.011 mm (0.0002–0.0004 in.)

Maximum oil clearance:

0.05 mm (0.0020 in.)

If the oil clearance is greater than maximum, replace the

bushing. If necessary, replace the piston and piston pin as a

set.

P02270 EM028B Z02381

P02277 EM0290 Z02382

P02275

EM0227