IGNITION SYSTEM – (2JZ–GE)

IG–5

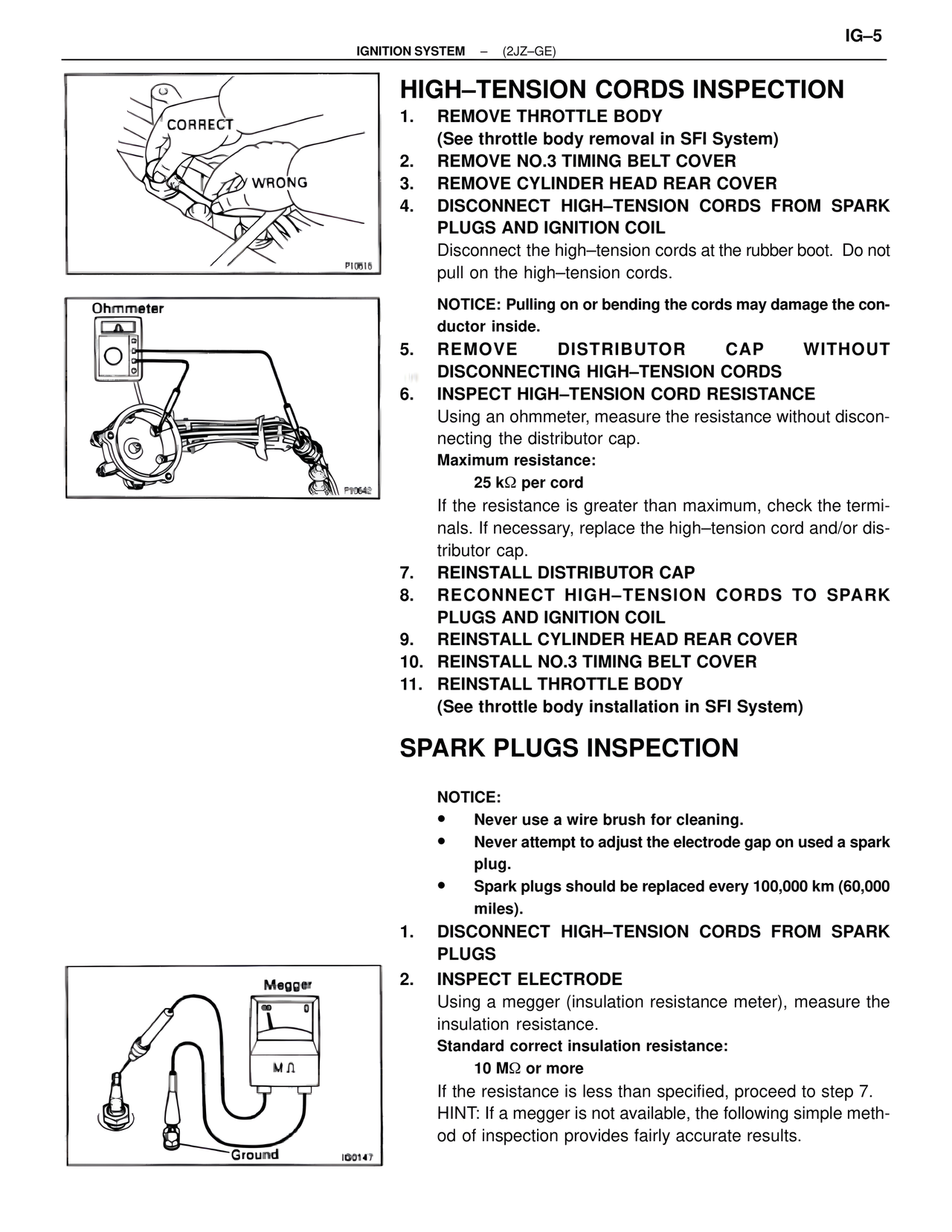

CORRECT

WRONG

P10618

Ohmmeter

P10642

HIGH–TENSION CORDS INSPECTION

1. REMOVE THROTTLE BODY

(See throttle body removal in SFI System)

2. REMOVE NO.3 TIMING BELT COVER

3. REMOVE CYLINDER HEAD REAR COVER

4. DISCONNECT HIGH–TENSION CORDS FROM SPARK PLUGS AND IGNITION COIL

Disconnect the high–tension cords at the rubber boot. Do not pull on the high–tension cords.

NOTICE: Pulling on or bending the cords may damage the conductor inside.

5. REMOVE DISTRIBUTOR CAP WITHOUT DISCONNECTING HIGH–TENSION CORDS

6. INSPECT HIGH–TENSION CORD RESISTANCE

Using an ohmmeter, measure the resistance without disconnecting the distributor cap.

Maximum resistance:

25 kΩ per cord

If the resistance is greater than maximum, check the terminals. If necessary, replace the high–tension cord and/or distributor cap.

7. REINSTALL DISTRIBUTOR CAP

8. RECONNECT HIGH–TENSION CORDS TO SPARK PLUGS AND IGNITION COIL

9. REINSTALL CYLINDER HEAD REAR COVER

10. REINSTALL NO.3 TIMING BELT COVER

11. REINSTALL THROTTLE BODY

(See throttle body installation in SFI System)

SPARK PLUGS INSPECTION

NOTICE:

• Never use a wire brush for cleaning.

• Never attempt to adjust the electrode gap on used a spark plug.

• Spark plugs should be replaced every 100,000 km (60,000 miles).

1. DISCONNECT HIGH–TENSION CORDS FROM SPARK PLUGS

2. INSPECT ELECTRODE

Using a megger (insulation resistance meter), measure the insulation resistance.

Standard correct insulation resistance:

10 MΩ or more

If the resistance is less than specified, proceed to step 7.

HINT: If a megger is not available, the following simple method of inspection provides fairly accurate results.

Megger

MΩ

Ground

IG0147