IN–31

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

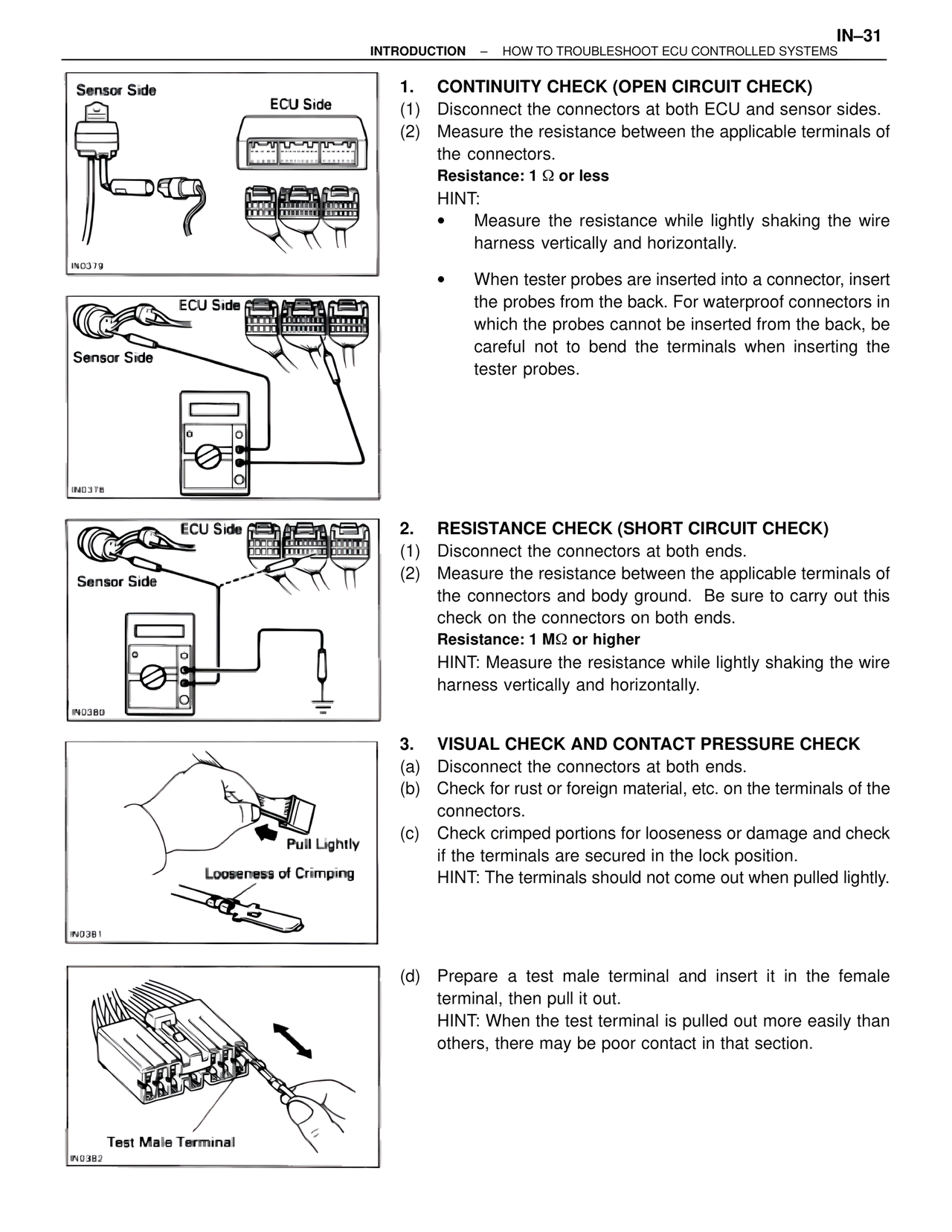

Sensor Side

ECU Side

IN0379

ECU Side

Sensor Side

IN0378

1. CONTINUITY CHECK (OPEN CIRCUIT CHECK)

(1) Disconnect the connectors at both ECU and sensor sides.

(2) Measure the resistance between the applicable terminals of

the connectors.

Resistance: 1 Ω or less

HINT:

• Measure the resistance while lightly shaking the wire

harness vertically and horizontally.

• When tester probes are inserted into a connector, insert

the probes from the back. For waterproof connectors in

which the probes cannot be inserted from the back, be

careful not to bend the terminals when inserting the

tester probes.

ECU Side

Sensor Side

IN0380

2. RESISTANCE CHECK (SHORT CIRCUIT CHECK)

(1) Disconnect the connectors at both ends.

(2) Measure the resistance between the applicable terminals of

the connectors and body ground. Be sure to carry out this

check on the connectors on both ends.

Resistance: 1 MΩ or higher

HINT: Measure the resistance while lightly shaking the wire

harness vertically and horizontally.

Pull Lightly

Looseness of Crimping

IN0381

3. VISUAL CHECK AND CONTACT PRESSURE CHECK

(a) Disconnect the connectors at both ends.

(b) Check for rust or foreign material, etc. on the terminals of the

connectors.

(c) Check crimped portions for looseness or damage and check

if the terminals are secured in the lock position.

HINT: The terminals should not come out when pulled lightly.

Test Male Terminal

IN0382

(d) Prepare a test male terminal and insert it in the female

terminal, then pull it out.

HINT: When the test terminal is pulled out more easily than

others, there may be poor contact in that section.