PR–13

PROPELLER SHAFT – PROPELLER SHAFT

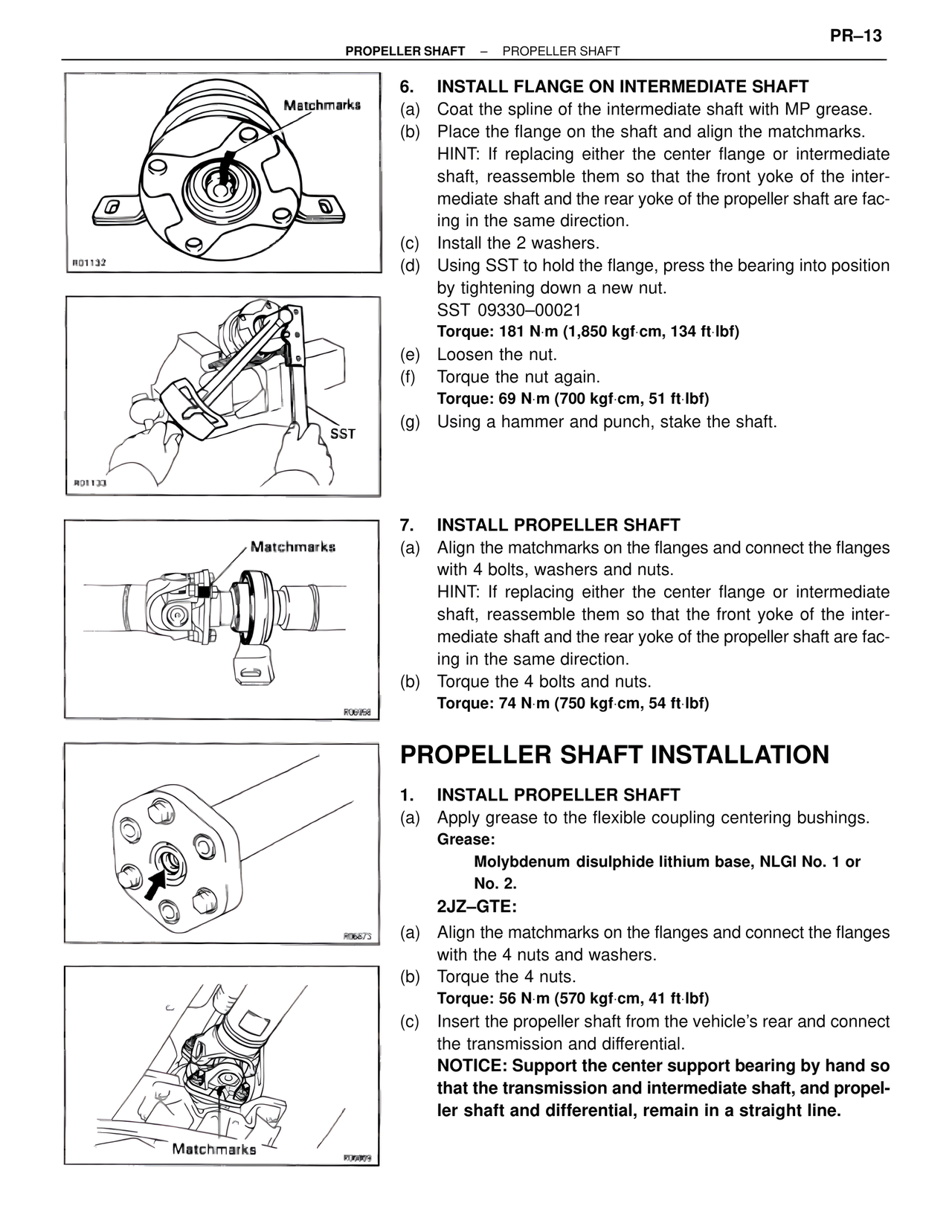

Matchmarks

R01132

SST

R01133

Matchmarks

R06958

R06873

Matchmarks

R06809

6. INSTALL FLANGE ON INTERMEDIATE SHAFT

(a) Coat the spline of the intermediate shaft with MP grease.

(b) Place the flange on the shaft and align the matchmarks.

HINT: If replacing either the center flange or intermediate

shaft, reassemble them so that the front yoke of the inter-

mediate shaft and the rear yoke of the propeller shaft are fac-

ing in the same direction.

(c) Install the 2 washers.

(d) Using SST to hold the flange, press the bearing into position

by tightening down a new nut.

SST 09330–00021

Torque: 181 N·m (1,850 kgf·cm, 134 ft·lbf)

(e) Loosen the nut.

(f) Torque the nut again.

Torque: 69 N·m (700 kgf·cm, 51 ft·lbf)

(g) Using a hammer and punch, stake the shaft.

7. INSTALL PROPELLER SHAFT

(a) Align the matchmarks on the flanges and connect the flanges

with 4 bolts, washers and nuts.

HINT: If replacing either the center flange or intermediate

shaft, reassemble them so that the front yoke of the inter-

mediate shaft and the rear yoke of the propeller shaft are fac-

ing in the same direction.

(b) Torque the 4 bolts and nuts.

Torque: 74 N·m (750 kgf·cm, 54 ft·lbf)

PROPELLER SHAFT INSTALLATION

1. INSTALL PROPELLER SHAFT

(a) Apply grease to the flexible coupling centering bushings.

Grease:

Molybdenum disulphide lithium base, NLGI No. 1 or

No. 2.

2JZ–GTE:

(a) Align the matchmarks on the flanges and connect the flanges

with the 4 nuts and washers.

(b) Torque the 4 nuts.

Torque: 56 N·m (570 kgf·cm, 41 ft·lbf)

(c) Insert the propeller shaft from the vehicle's rear and connect

the transmission and differential.

NOTICE: Support the center support bearing by hand so

that the transmission and intermediate shaft, and propel-

ler shaft and differential, remain in a straight line.