EG–158

ENGINE – TURBOCHARGER SYSTEM (2JZ-GTE)

TURBOCHARGER COMPONENTS INSPECTION

Turbochargers

1. INSPECT TURBINE SHAFT ROTATION

Grasp the edge of the turbine wheel and turn it. Check that the impeller wheel turns smoothly.

If the impeller wheel does not turn or if it turns with a drag, replace the turbocharger assembly.

2. INSPECT AXIAL PLAY OF TURBINE SHAFT

(a) Using a dial indicator, insert the needle of the dial indicator into the air tube side.

(b) Move the turbine shaft in an axial direction, measure the axial play of the turbine shaft.

Maximum axial play:

0.110 mm (0.0045 in.)

If the axial play is greater than maximum, replace the turbocharger assembly.

3. INSPECT RADIAL PLAY OF TURBINE SHAFT

(a) Using a dial indicator, insert the needle of the dial indicator into the oil outlet hole and set it in the center of the turbine shaft.

(b) Move the turbine shaft in a radial direction, measure the radial play of the turbine shaft.

Maximum radial play:

0.162 mm (0.0064 in.)

If the axial play is greater than maximum, replace the turbocharger assembly.

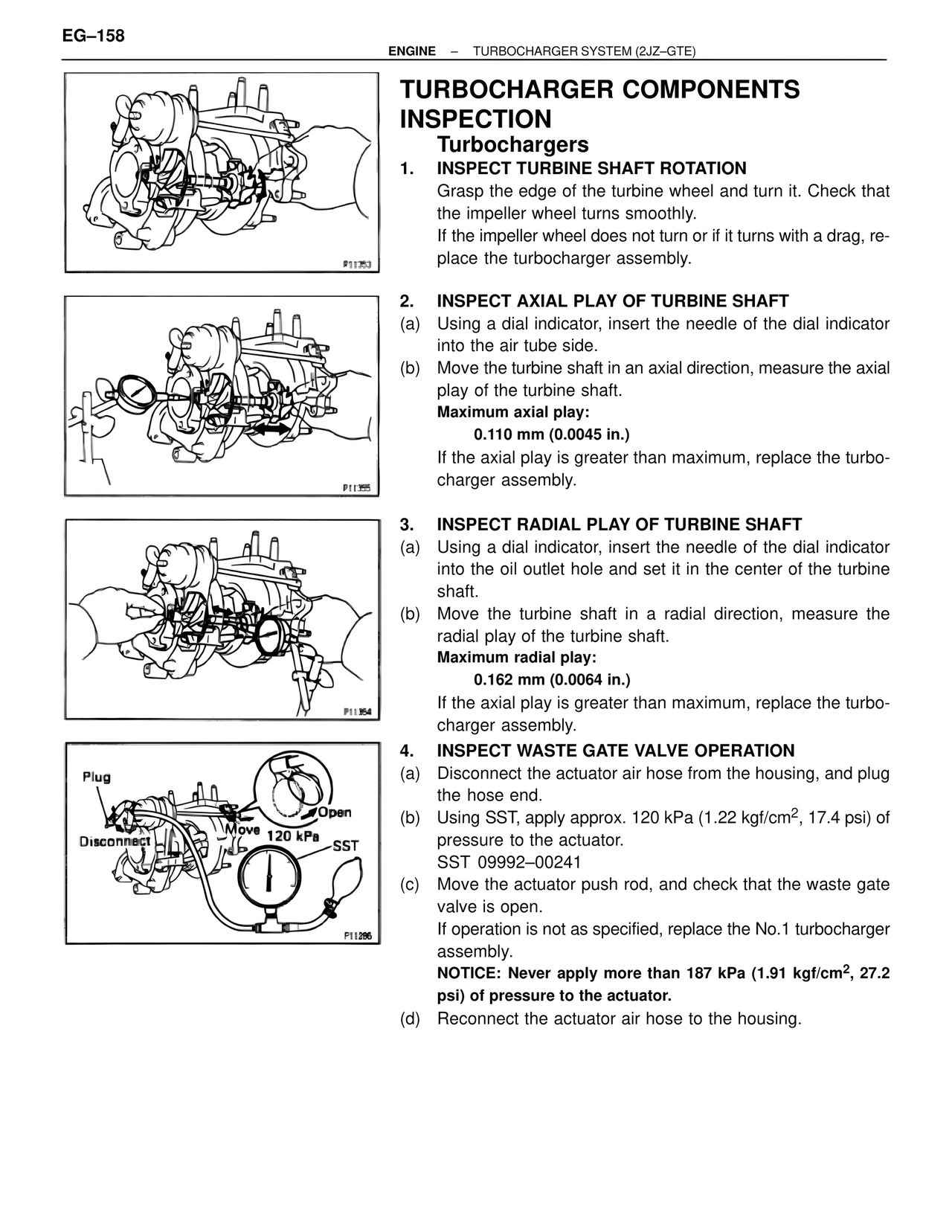

4. INSPECT WASTE GATE VALVE OPERATION

(a) Disconnect the actuator air hose from the housing, and plug the hose end.

(b) Using SST, apply approx. 120 kPa (1.22 kgf/cm2, 17.4 psi) of pressure to the actuator.

SST 09992–00241

(c) Move the actuator push rod, and check that the waste gate valve is open.

If operation is not as specified, replace the No.1 turbocharger assembly.

NOTICE: Never apply more than 187 kPa (1.91 kgf/cm2, 27.2 psi) of pressure to the actuator.

(d) Reconnect the actuator air hose to the housing.

Plug

Open

Move

120 kPa

Disconnect

SST

P11286