INSPECTION PROCEDURE

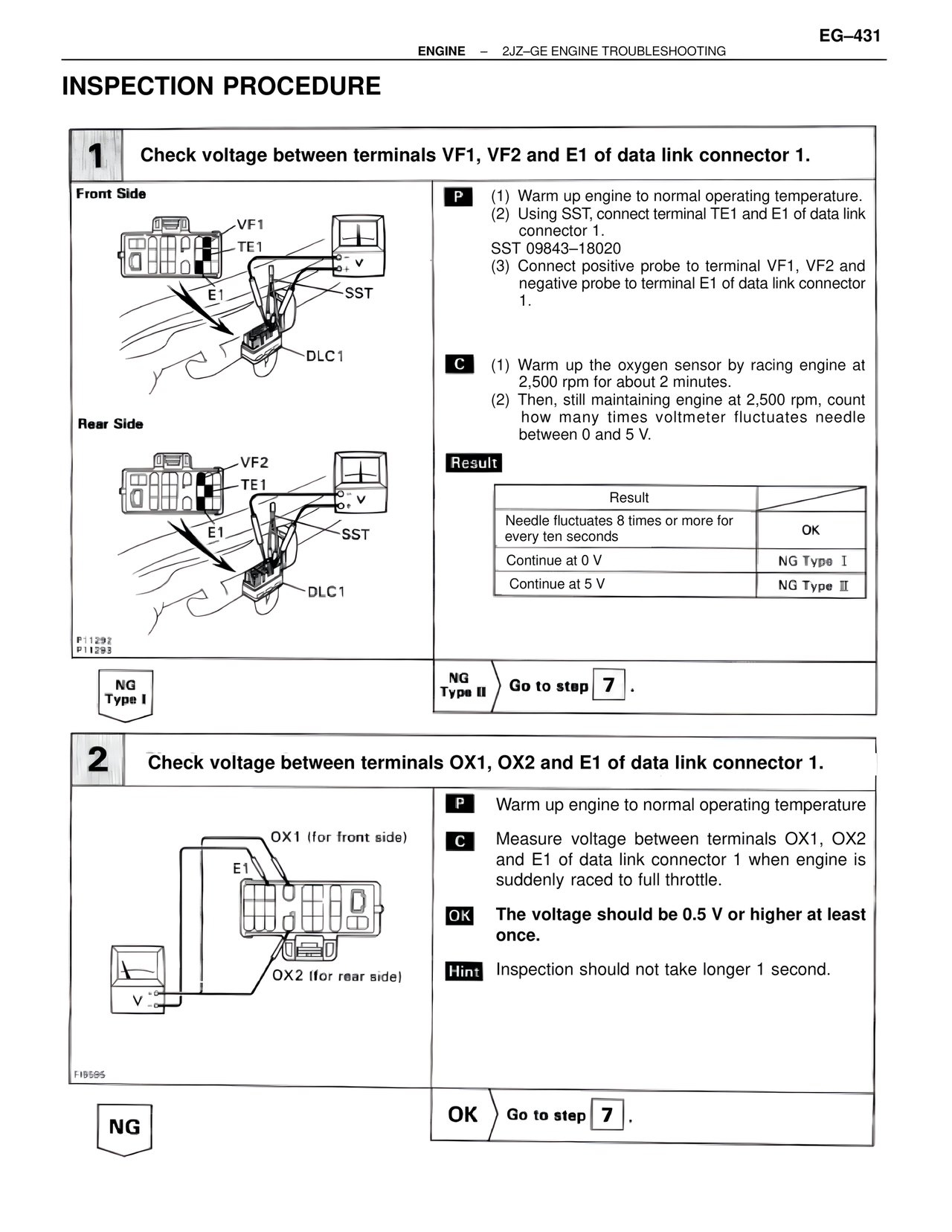

1 Check voltage between terminals VF1, VF2 and E1 of data link connector 1.

Front Side

VF1

TE1

E1

SST

DLC1

Rear Side

VF2

TE1

E1

SST

DLC1

P11292

P11295

P (1) Warm up engine to normal operating temperature.

(2) Using SST, connect terminal TE1 and E1 of data link connector 1.

SST 09843-18020

(3) Connect positive probe to terminal VF1, VF2 and negative probe to terminal E1 of data link connector 1.

C (1) Warm up the oxygen sensor by racing engine at 2,500 rpm for about 2 minutes.

(2) Then, still maintaining engine at 2,500 rpm, count how many times voltmeter fluctuates needle between 0 and 5 V.

Result

Result

Needle fluctuates 8 times or more for every ten seconds | OK

Continue at 0 V | NG Type I

Continue at 5 V | NG Type II

NG Type I

NG Type II Go to step 7 .

2 Check voltage between terminals OX1, OX2 and E1 of data link connector 1.

OX1 (for front side)

E1

OX2 (for rear side)

F19595

P Warm up engine to normal operating temperature

C Measure voltage between terminals OX1, OX2 and E1 of data link connector 1 when engine is suddenly raced to full throttle.

OK The voltage should be 0.5 V or higher at least once.

Hint Inspection should not take longer 1 second.

NG

OK Go to step 7 .