CIRCUIT INSPECTION

DTC 12 G NE Signal Circuit (No.1)

CIRCUIT DESCRIPTION

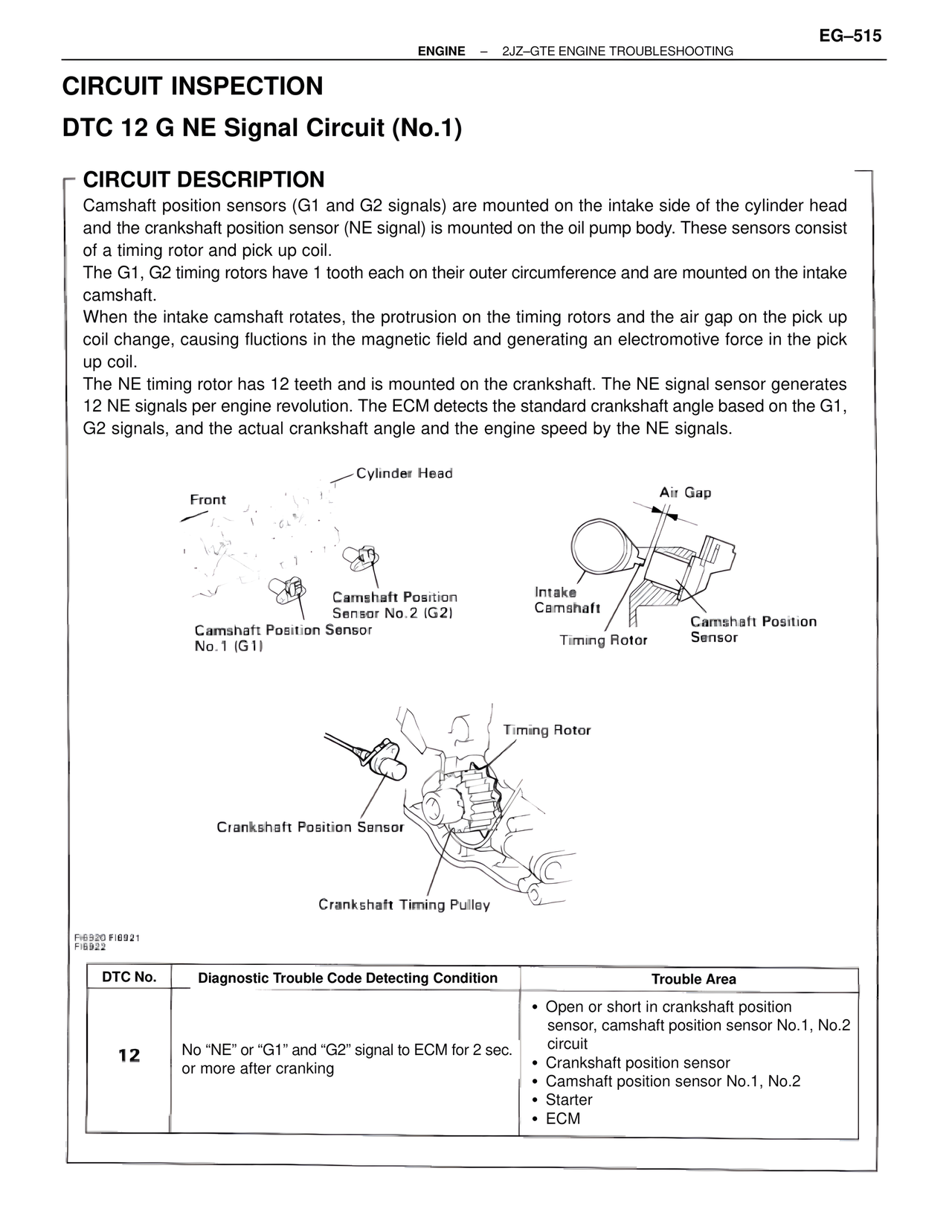

Camshaft position sensors (G1 and G2 signals) are mounted on the intake side of the cylinder head

and the crankshaft position sensor (NE signal) is mounted on the oil pump body. These sensors consist

of a timing rotor and pick up coil.

The G1, G2 timing rotors have 1 tooth each on their outer circumference and are mounted on the intake

camshaft.

When the intake camshaft rotates, the protrusion on the timing rotors and the air gap on the pick up

coil change, causing fluctions in the magnetic field and generating an electromotive force in the pick

up coil.

The NE timing rotor has 12 teeth and is mounted on the crankshaft. The NE signal sensor generates

12 NE signals per engine revolution. The ECM detects the standard crankshaft angle based on the G1,

G2 signals, and the actual crankshaft angle and the engine speed by the NE signals.

Cylinder Head

Front

Air Gap

Camshaft Position

Sensor No.2 (G2)

Intake

Camshaft

Camshaft Position Sensor

No.1 (G1)

Camshaft Position

Sensor

Timing Rotor

Timing Rotor

Crankshaft Position Sensor

Crankshaft Timing Pulley

FI6920 FI6921

FI6922

DTC No. | Diagnostic Trouble Code Detecting Condition | Trouble Area

12 | No "NE" or "G1" and "G2" signal to ECM for 2 sec.

or more after cranking | • Open or short in crankshaft position

sensor, camshaft position sensor No.1, No.2

circuit

• Crankshaft position sensor

• Camshaft position sensor No.1, No.2

• Starter

• ECM