MT1–25

W58 MANUAL TRANSMISSION – INPUT SHAFT

(d) Using a feeler gauge, measure the clearance between the

synchronizer ring back and gear spline end.

Minimum clearance:

0.5 mm (0.020 in.)

HINT: When replacing either a synchronizer ring or gear, ap-

ply a small amount of fine lapping compound between the

synchronizer ring and gear cone.

Lightly rub the synchronizer ring and gear cone together.

NOTICE:

• When replacing both the synchronizer ring and gear,

there is no need to apply any compound or to rub them

together.

• NOTICE: Ensure the fine lapping compound is

completely washed off after rubbing.

BEARING REPLACEMENT

IF NECESSARY, REPLACE INPUT SHAFT BEARING

(a) Using a snap ring expander, remove the snap ring.

(b) Using a press, remove the bearing.

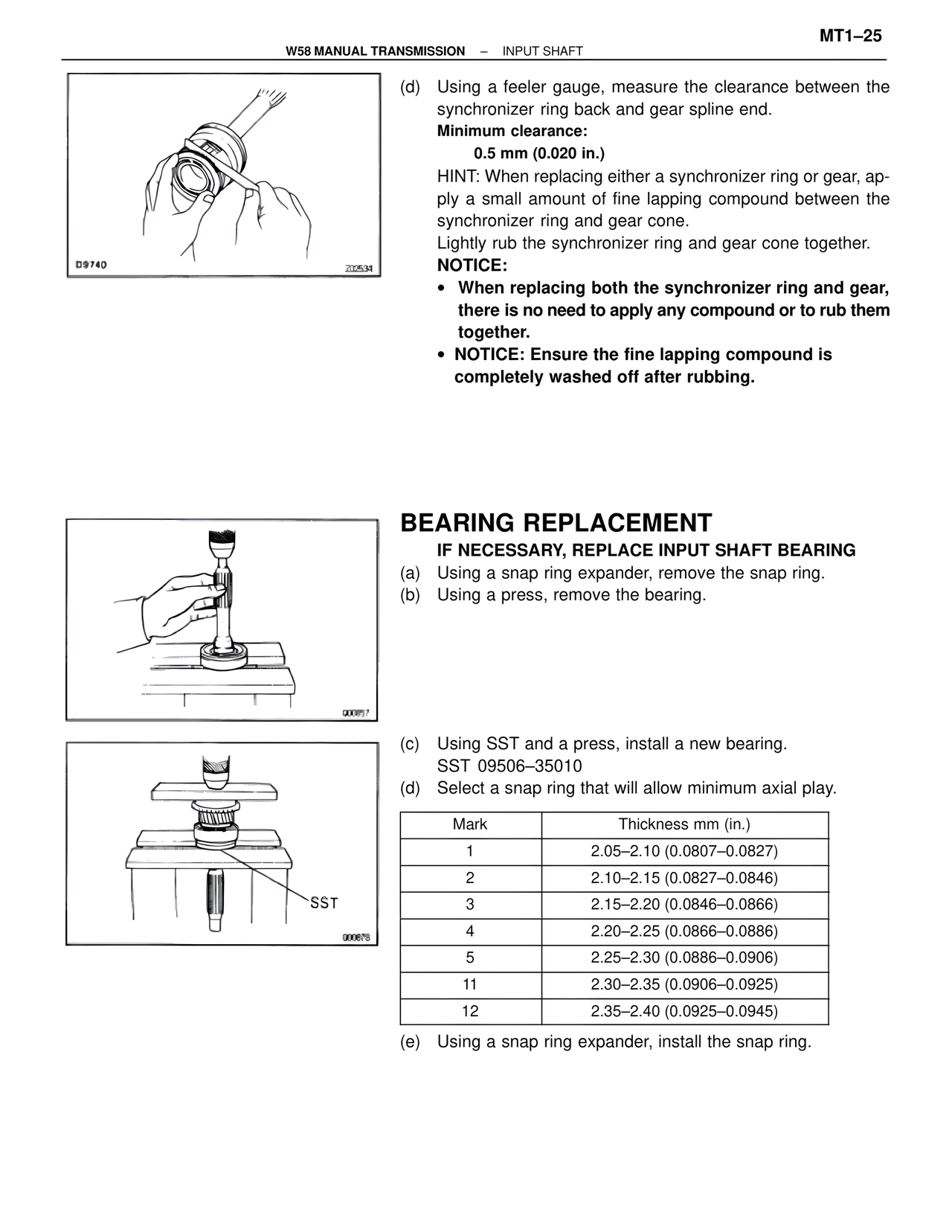

(c) Using SST and a press, install a new bearing.

SST 09506–35010

(d) Select a snap ring that will allow minimum axial play.

Mark | Thickness mm (in.)

1 | 2.05–2.10 (0.0807–0.0827)

2 | 2.10–2.15 (0.0827–0.0846)

3 | 2.15–2.20 (0.0846–0.0866)

4 | 2.20–2.25 (0.0866–0.0886)

5 | 2.25–2.30 (0.0886–0.0906)

11 | 2.30–2.35 (0.0906–0.0925)

12 | 2.35–2.40 (0.0925–0.0945)

(e) Using a snap ring expander, install the snap ring.

D9740

202534

000857

SST

000878