MT1–36

W58 MANUAL TRANSMISSION – COUNTER GEAR AND REVERSE IDLER GEAR

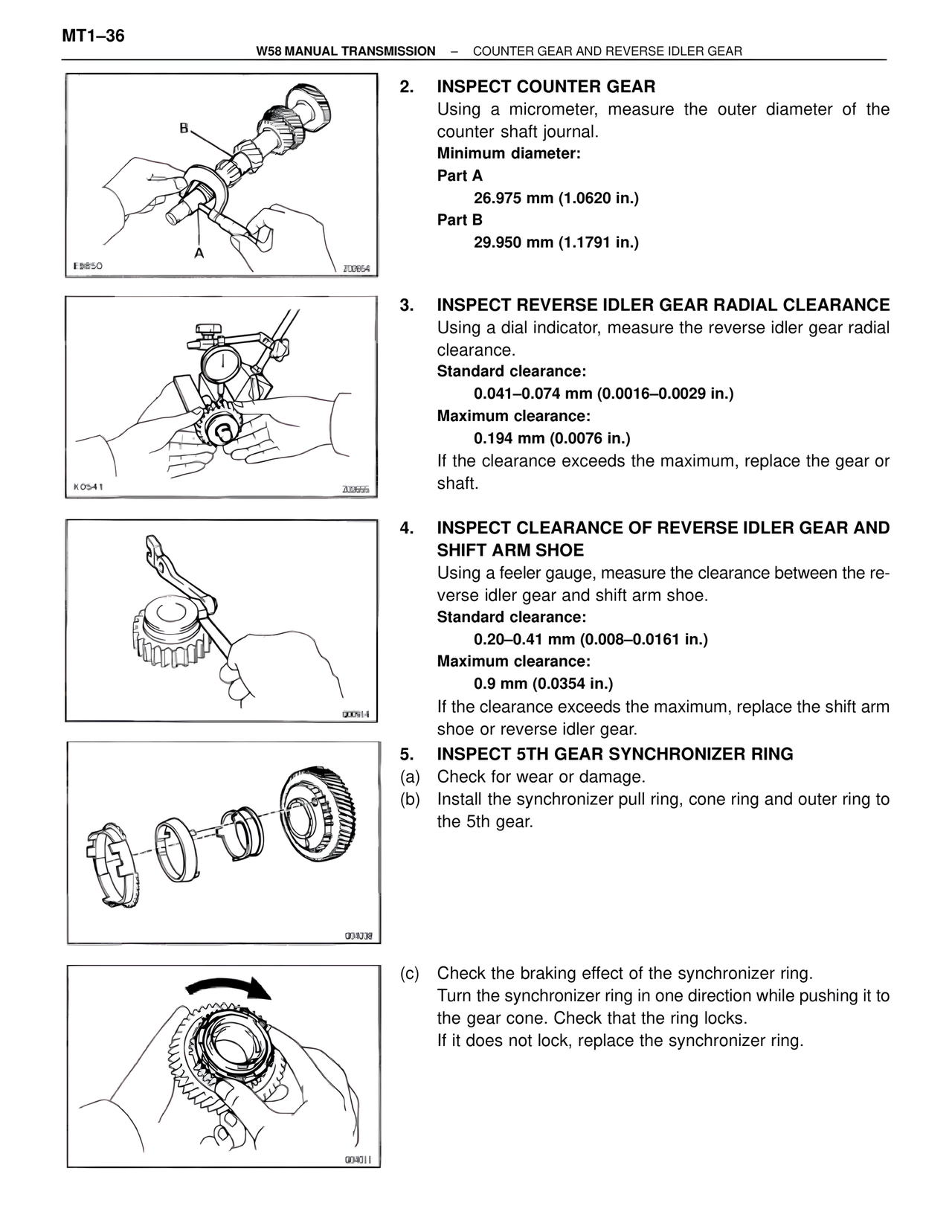

2. INSPECT COUNTER GEAR

Using a micrometer, measure the outer diameter of the counter shaft journal.

Minimum diameter:

Part A

26.975 mm (1.0620 in.)

Part B

29.950 mm (1.1791 in.)

3. INSPECT REVERSE IDLER GEAR RADIAL CLEARANCE

Using a dial indicator, measure the reverse idler gear radial clearance.

Standard clearance:

0.041–0.074 mm (0.0016–0.0029 in.)

Maximum clearance:

0.194 mm (0.0076 in.)

If the clearance exceeds the maximum, replace the gear or shaft.

4. INSPECT CLEARANCE OF REVERSE IDLER GEAR AND SHIFT ARM SHOE

Using a feeler gauge, measure the clearance between the reverse idler gear and shift arm shoe.

Standard clearance:

0.20–0.41 mm (0.008–0.0161 in.)

Maximum clearance:

0.9 mm (0.0354 in.)

If the clearance exceeds the maximum, replace the shift arm shoe or reverse idler gear.

5. INSPECT 5TH GEAR SYNCHRONIZER RING

(a) Check for wear or damage.

(b) Install the synchronizer pull ring, cone ring and outer ring to the 5th gear.

(c) Check the braking effect of the synchronizer ring.

Turn the synchronizer ring in one direction while pushing it to the gear cone. Check that the ring locks.

If it does not lock, replace the synchronizer ring.