MT1–6

W58 MANUAL TRANSMISSION – PRECAUTION

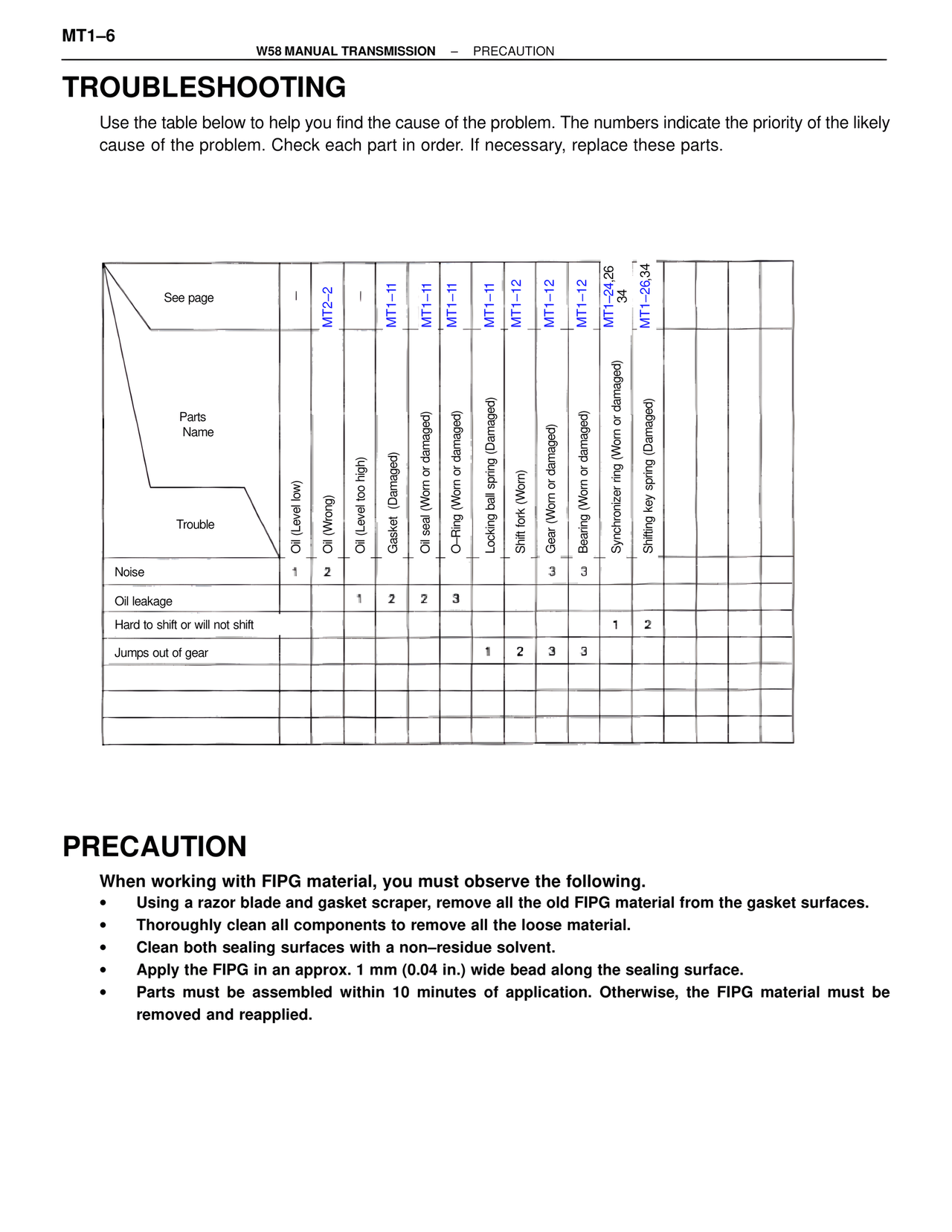

TROUBLESHOOTING

Use the table below to help you find the cause of the problem. The numbers indicate the priority of the likely cause of the problem. Check each part in order. If necessary, replace these parts.

See page

Parts Name

Trouble

MT2–2

MT1–11

MT1–11

MT1–11

MT1–11

MT1–12

MT1–12

MT1–12

MT1–24,26,34

MT1–26,34

Oil (Level low)

Oil (Wrong)

Oil (Level too high)

Gasket (Damaged)

Oil seal (Worn or damaged)

O–Ring (Worn or damaged)

Locking ball spring (Damaged)

Shift fork (Worn)

Gear (Worn or damaged)

Bearing (Worn or damaged)

Synchronizer ring (Worn or damaged)

Shifting key spring (Damaged)

Noise | 1 | 2 | | | | | | 3 | 3 | | |

Oil leakage | | | 1 | 2 | 2 | 3 | | | | | |

Hard to shift or will not shift | | | | | | | | | | 1 | 2 |

Jumps out of gear | | | | | | 1 | 2 | 3 | 3 | | |

PRECAUTION

When working with FIPG material, you must observe the following.

• Using a razor blade and gasket scraper, remove all the old FIPG material from the gasket surfaces.

• Thoroughly clean all components to remove all the loose material.

• Clean both sealing surfaces with a non–residue solvent.

• Apply the FIPG in an approx. 1 mm (0.04 in.) wide bead along the sealing surface.

• Parts must be assembled within 10 minutes of application. Otherwise, the FIPG material must be removed and reapplied.