BR–34

BRAKE SYSTEM – REAR BRAKE (2JZ–GTE)

REAR BRAKE COMPONENTS

INSPECTION AND REPAIR

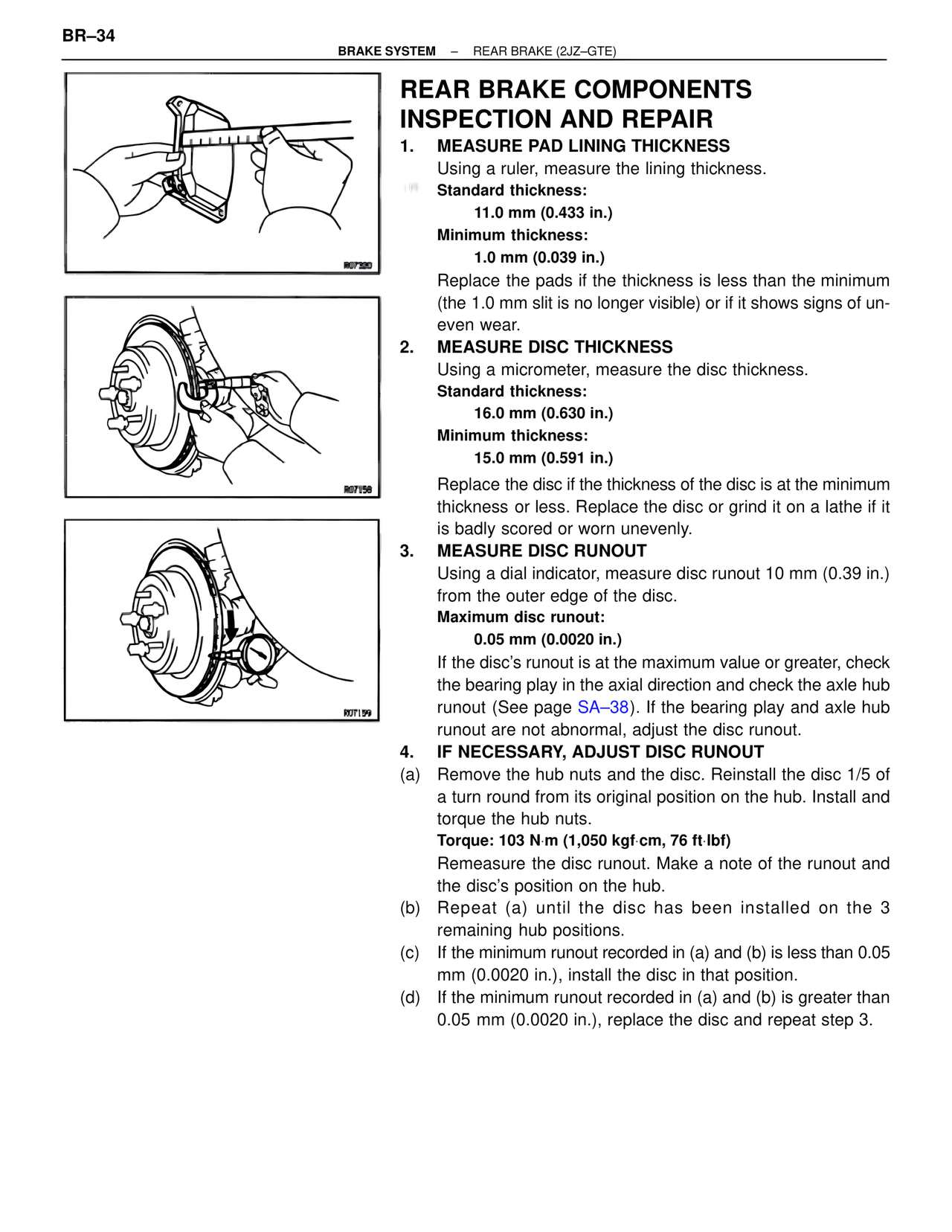

1. MEASURE PAD LINING THICKNESS

Using a ruler, measure the lining thickness.

Standard thickness:

11.0 mm (0.433 in.)

Minimum thickness:

1.0 mm (0.039 in.)

Replace the pads if the thickness is less than the minimum

(the 1.0 mm slit is no longer visible) or if it shows signs of un-

even wear.

2. MEASURE DISC THICKNESS

Using a micrometer, measure the disc thickness.

Standard thickness:

16.0 mm (0.630 in.)

Minimum thickness:

15.0 mm (0.591 in.)

Replace the disc if the thickness of the disc is at the minimum

thickness or less. Replace the disc or grind it on a lathe if it

is badly scored or worn unevenly.

3. MEASURE DISC RUNOUT

Using a dial indicator, measure disc runout 10 mm (0.39 in.)

from the outer edge of the disc.

Maximum disc runout:

0.05 mm (0.0020 in.)

If the disc's runout is at the maximum value or greater, check

the bearing play in the axial direction and check the axle hub

runout (See page SA–38). If the bearing play and axle hub

runout are not abnormal, adjust the disc runout.

4. IF NECESSARY, ADJUST DISC RUNOUT

(a) Remove the hub nuts and the disc. Reinstall the disc 1/5 of

a turn round from its original position on the hub. Install and

torque the hub nuts.

Torque: 103 N·m (1,050 kgf·cm, 76 ft·lbf)

Remeasure the disc runout. Make a note of the runout and

the disc's position on the hub.

(b) Repeat (a) until the disc has been installed on the 3

remaining hub positions.

(c) If the minimum runout recorded in (a) and (b) is less than 0.05

mm (0.0020 in.), install the disc in that position.

(d) If the minimum runout recorded in (a) and (b) is greater than

0.05 mm (0.0020 in.), replace the disc and repeat step 3.

R07320

R07156

R07159