EG–356

ENGINE – COOLING SYSTEM

Engine Coolant Temperature (ECT) Switch

ECT SWITCH INSPECTION

1. REMOVE ENGINE UNDER COVER

2. DRAIN ENGINE COOLANT

3. REMOVE ECT SWITCH

(a) Disconnect the ECT switch connector.

(b) Remove the ECT switch.

(c) Remove the O–ring from the ECT switch.

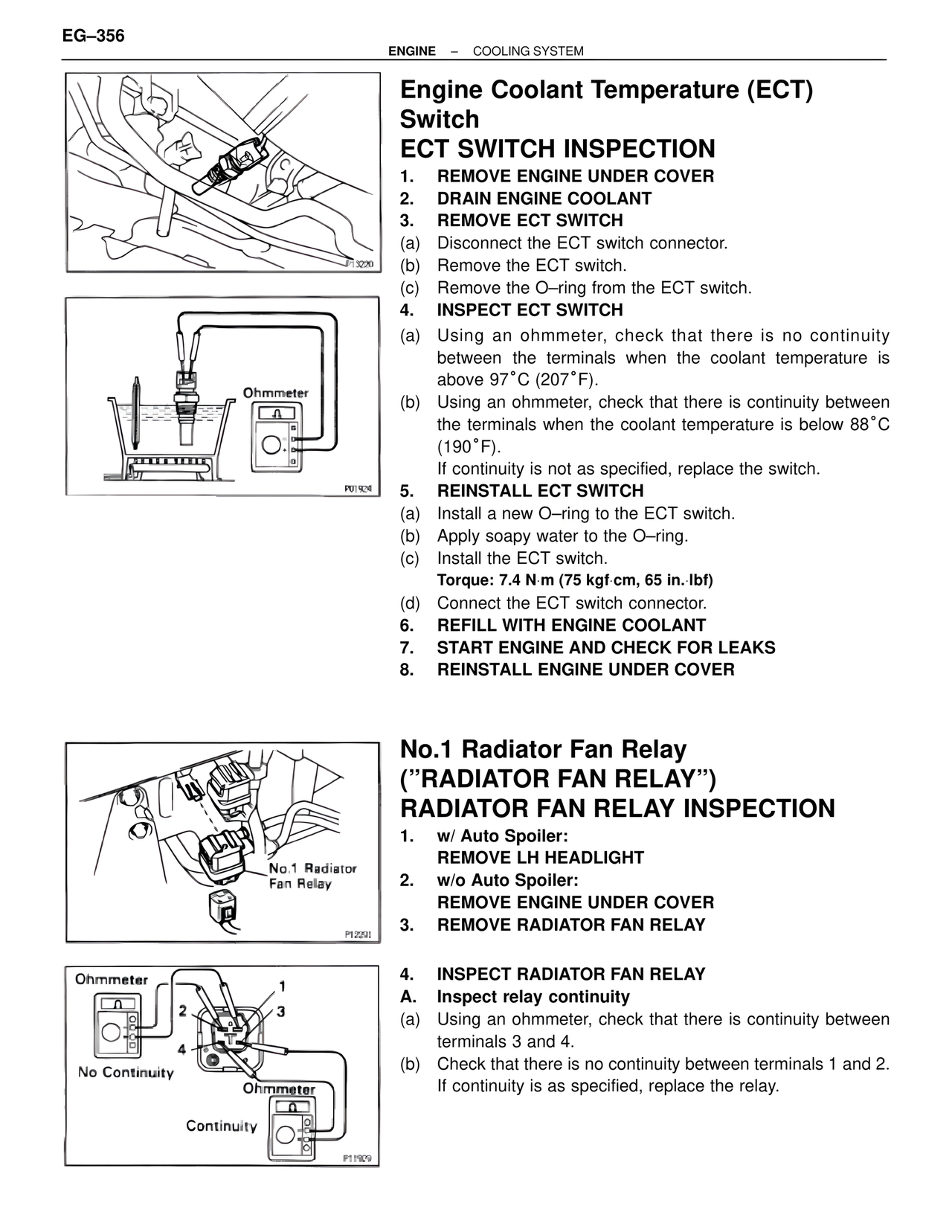

4. INSPECT ECT SWITCH

(a) Using an ohmmeter, check that there is no continuity between the terminals when the coolant temperature is above 97°C (207°F).

(b) Using an ohmmeter, check that there is continuity between the terminals when the coolant temperature is below 88°C (190°F).

If continuity is not as specified, replace the switch.

5. REINSTALL ECT SWITCH

(a) Install a new O–ring to the ECT switch.

(b) Apply soapy water to the O–ring.

(c) Install the ECT switch.

Torque: 7.4 N·m (75 kgf·cm, 65 in.·lbf)

(d) Connect the ECT switch connector.

6. REFILL WITH ENGINE COOLANT

7. START ENGINE AND CHECK FOR LEAKS

8. REINSTALL ENGINE UNDER COVER

P13290

Ohmmeter

P01929

No.1 Radiator Fan Relay

("RADIATOR FAN RELAY")

RADIATOR FAN RELAY INSPECTION

1. w/ Auto Spoiler:

REMOVE LH HEADLIGHT

2. w/o Auto Spoiler:

REMOVE ENGINE UNDER COVER

3. REMOVE RADIATOR FAN RELAY

No.1 Radiator Fan Relay

P12291

4. INSPECT RADIATOR FAN RELAY

A. Inspect relay continuity

(a) Using an ohmmeter, check that there is continuity between terminals 3 and 4.

(b) Check that there is no continuity between terminals 1 and 2.

If continuity is as specified, replace the relay.

Ohmmeter

1

2

3

4

No Continuity

Ohmmeter

Continuity

P11929