INSTALLATION

PRE–WELDING MEASUREMENTS

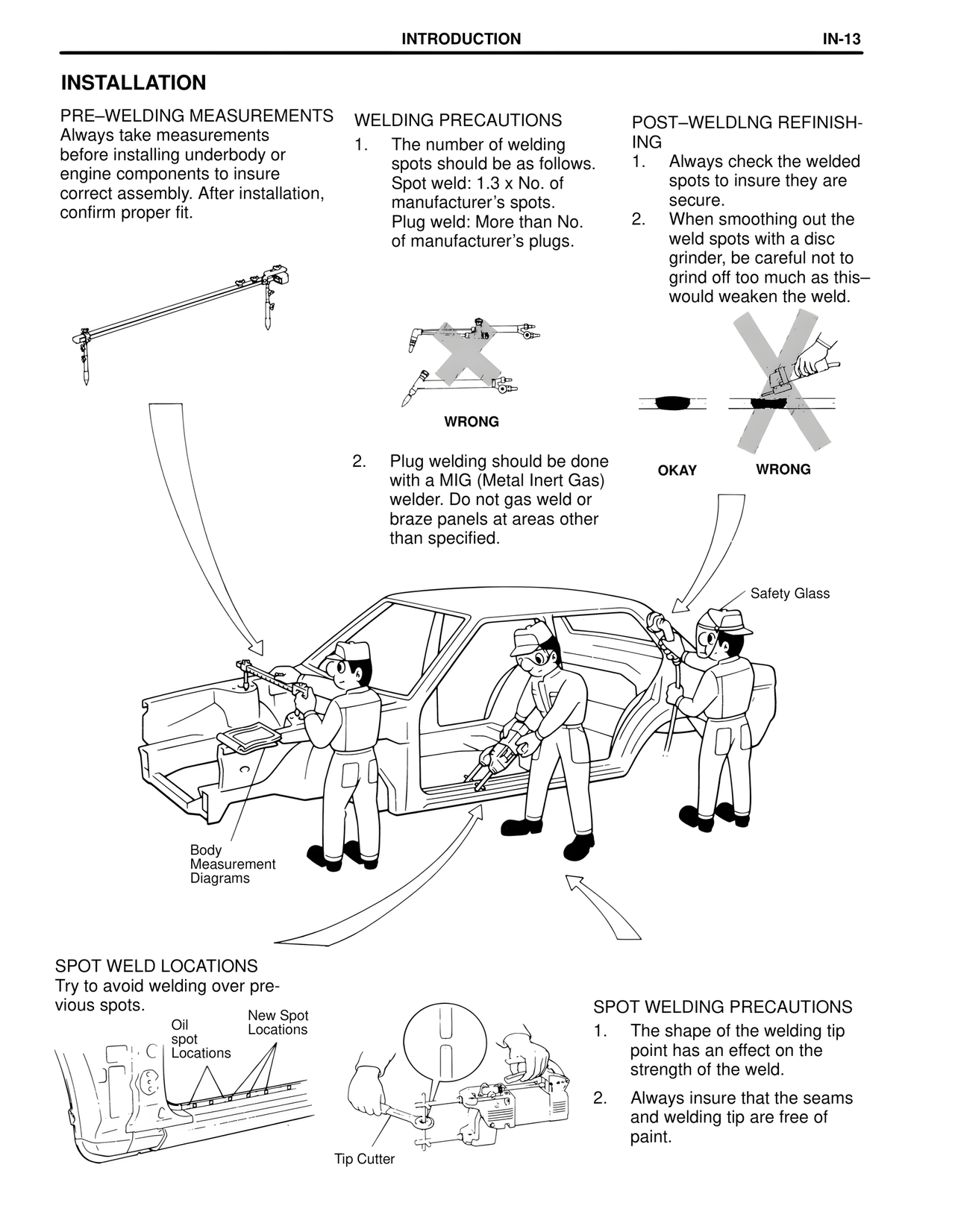

Always take measurements before installing underbody or engine components to insure correct assembly. After installation, confirm proper fit.

WELDING PRECAUTIONS

1. The number of welding spots should be as follows.

Spot weld: 1.3 x No. of manufacturer's spots.

Plug weld: More than No. of manufacturer's plugs.

WRONG

2. Plug welding should be done with a MIG (Metal Inert Gas) welder. Do not gas weld or braze panels at areas other than specified.

POST–WELDLNG REFINISHING

1. Always check the welded spots to insure they are secure.

2. When smoothing out the weld spots with a disc grinder, be careful not to grind off too much as this–would weaken the weld.

OKAY WRONG

Safety Glass

Body Measurement Diagrams

SPOT WELD LOCATIONS

Try to avoid welding over previous spots.

Oil spot Locations

New Spot Locations

Tip Cutter

SPOT WELDING PRECAUTIONS

1. The shape of the welding tip point has an effect on the strength of the weld.

2. Always insure that the seams and welding tip are free of paint.