IN-12 INTRODUCTION

PREPARATION FOR INSTALLATION

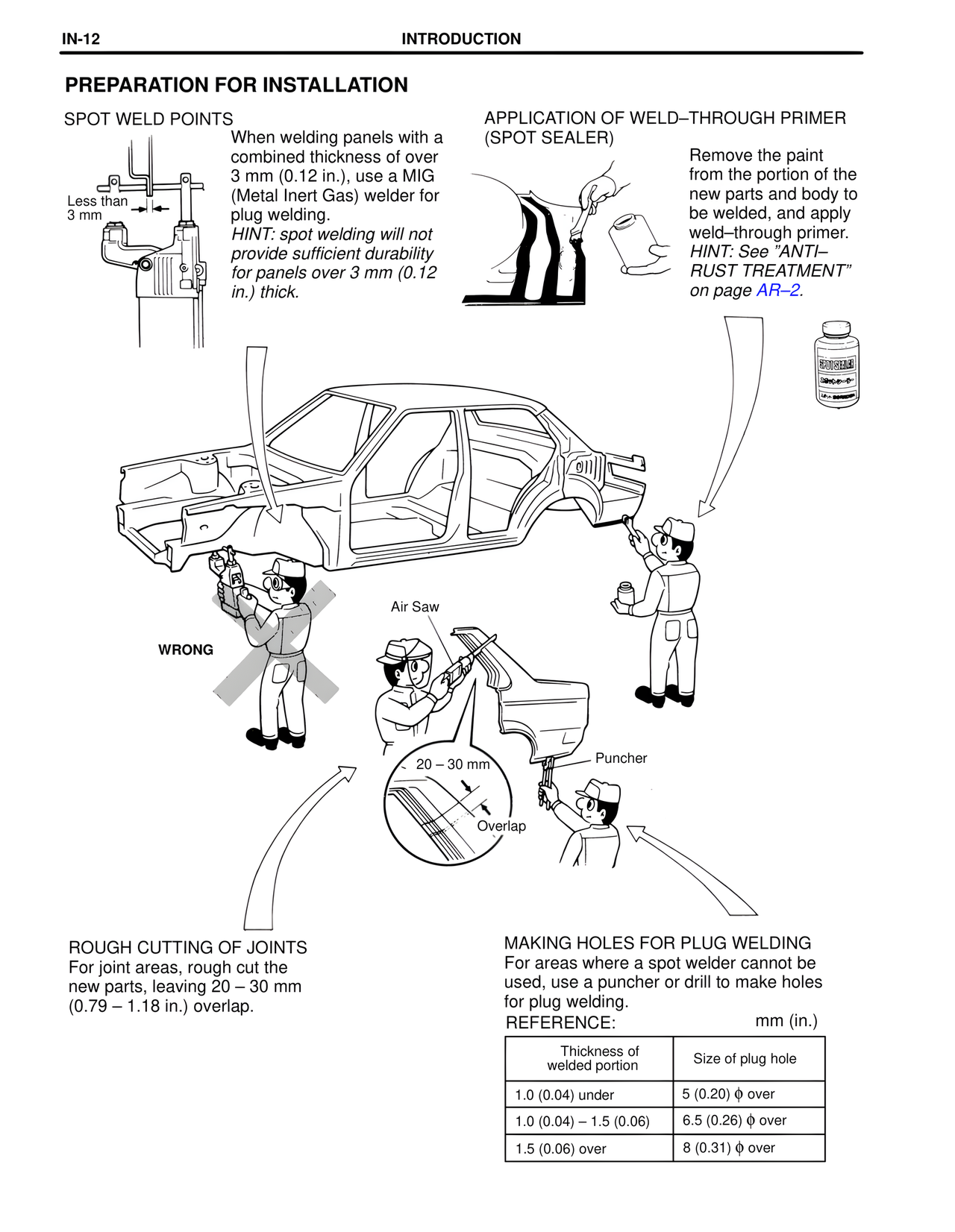

SPOT WELD POINTS

When welding panels with a combined thickness of over 3 mm (0.12 in.), use a MIG (Metal Inert Gas) welder for plug welding.

HINT: spot welding will not provide sufficient durability for panels over 3 mm (0.12 in.) thick.

Less than 3 mm

APPLICATION OF WELD–THROUGH PRIMER (SPOT SEALER)

Remove the paint from the portion of the new parts and body to be welded, and apply weld–through primer.

HINT: See "ANTI–RUST TREATMENT" on page AR–2.

WRONG

Air Saw

20 – 30 mm

Overlap

Puncher

ROUGH CUTTING OF JOINTS

For joint areas, rough cut the new parts, leaving 20 – 30 mm (0.79 – 1.18 in.) overlap.

MAKING HOLES FOR PLUG WELDING

For areas where a spot welder cannot be used, use a puncher or drill to make holes for plug welding.

REFERENCE: mm (in.)

Thickness of welded portion | Size of plug hole

1.0 (0.04) under | 5 (0.20) φ over

1.0 (0.04) – 1.5 (0.06) | 6.5 (0.26) φ over

1.5 (0.06) over | 8 (0.31) φ over