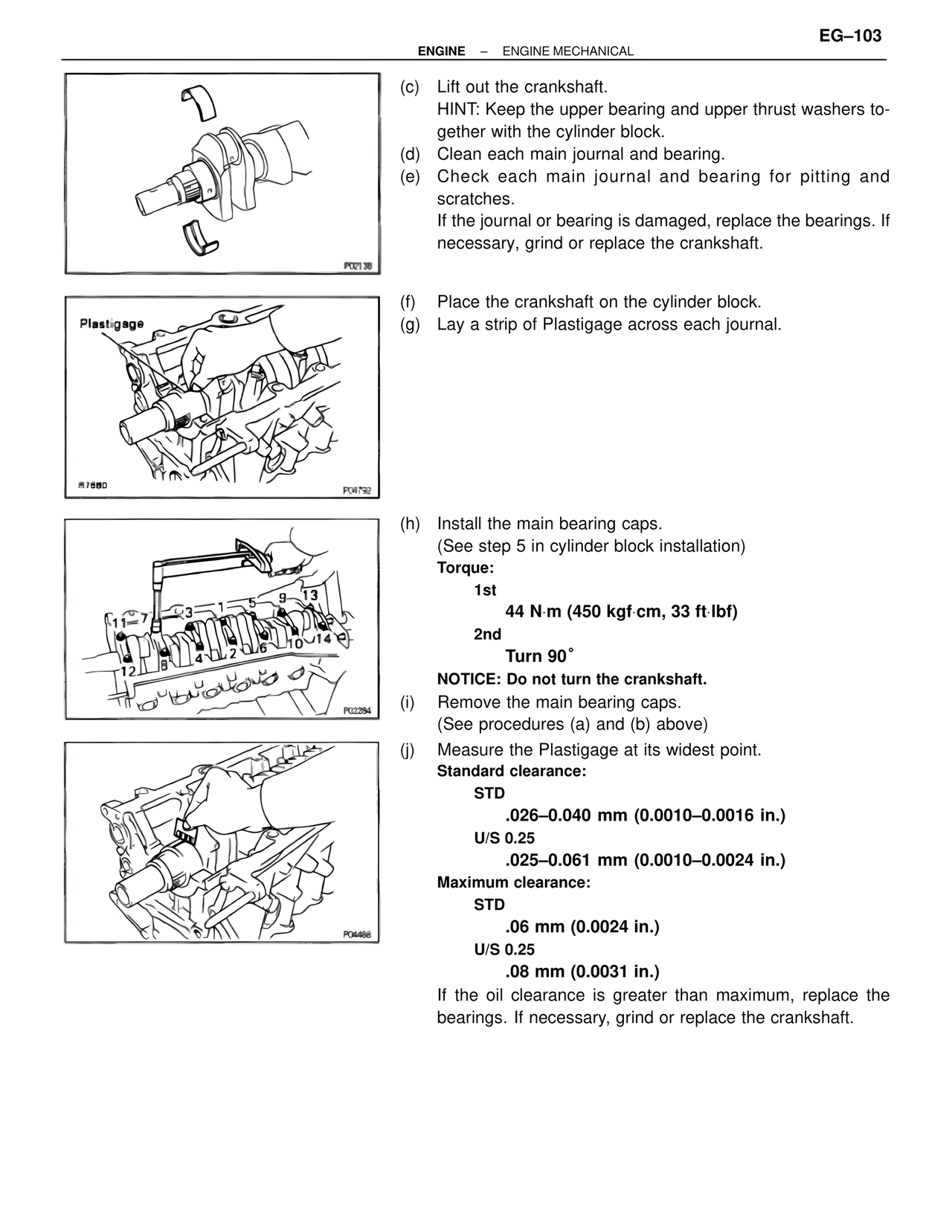

(c) Lift out the crankshaft.

HINT: Keep the upper bearing and upper thrust washers together with the cylinder block.

(d) Clean each main journal and bearing.

(e) Check each main journal and bearing for pitting and scratches.

If the journal or bearing is damaged, replace the bearings. If necessary, grind or replace the crankshaft.

Plastigage

(f) Place the crankshaft on the cylinder block.

(g) Lay a strip of Plastigage across each journal.

(h) Install the main bearing caps.

(See step 5 in cylinder block installation)

Torque:

1st

44 N·m (450 kgf·cm, 33 ft·lbf)

2nd

Turn 90°

NOTICE: Do not turn the crankshaft.

(i) Remove the main bearing caps.

(See procedures (a) and (b) above)

(j) Measure the Plastigage at its widest point.

Standard clearance:

STD

.026–0.040 mm (0.0010–0.0016 in.)

U/S 0.25

.025–0.061 mm (0.0010–0.0024 in.)

Maximum clearance:

STD

.06 mm (0.0024 in.)

U/S 0.25

.08 mm (0.0031 in.)

If the oil clearance is greater than maximum, replace the bearings. If necessary, grind or replace the crankshaft.