EG–106

ENGINE – ENGINE MECHANICAL

CYLINDER BLOCK INSPECTION

1. CLEAN CYLINDER BLOCK

A. Remove gasket material

Using a gasket scraper, remove all the gasket material from

the cylinder block surface.

B. Clean cylinder block

Using a soft brush and solvent, thoroughly clean the cylinder

block.

2. INSPECT CYLINDER BLOCK SURFACE FOR FLATNESS

Using precision straight edge and feeler gauge, measure the

surfaces of the cylinder block for warpage.

Maximum warpage:

0.07 mm (0.0028 in.)

If warpage is greater than maximum, replace the cylinder

block.

3. INSPECT CYLINDER FOR VERTICAL SCRATCHES

Visually check the cylinder for vertical scratches.

If deep scratches are present, replace the cylinder block.

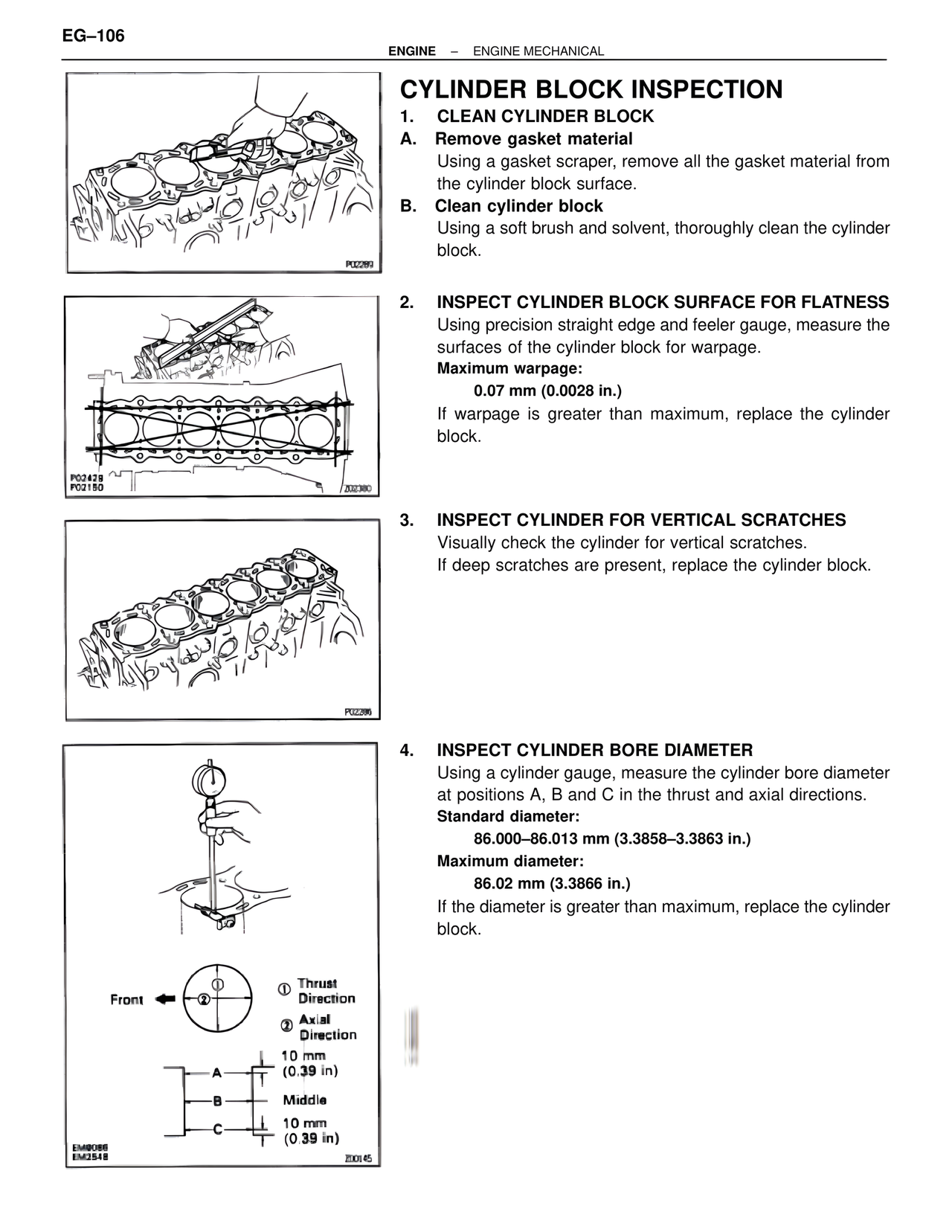

4. INSPECT CYLINDER BORE DIAMETER

Using a cylinder gauge, measure the cylinder bore diameter

at positions A, B and C in the thrust and axial directions.

Standard diameter:

86.000–86.013 mm (3.3858–3.3863 in.)

Maximum diameter:

86.02 mm (3.3866 in.)

If the diameter is greater than maximum, replace the cylinder

block.

Front ←

① Thrust

Direction

② Axial

Direction

A 10 mm

(0.39 in)

B Middle

C 10 mm

(0.39 in)

P02289

P02428

P02150

Z02380

P02286

EM8086

EM2548

Z00145