ENGINE – ENGINE MECHANICAL

EG–107

5. REMOVE CYLINDER RIDGE

If the wear is less than 0.2 mm (0.008 in.), using a ridge reamer, grind the top of the cylinder.

P02288

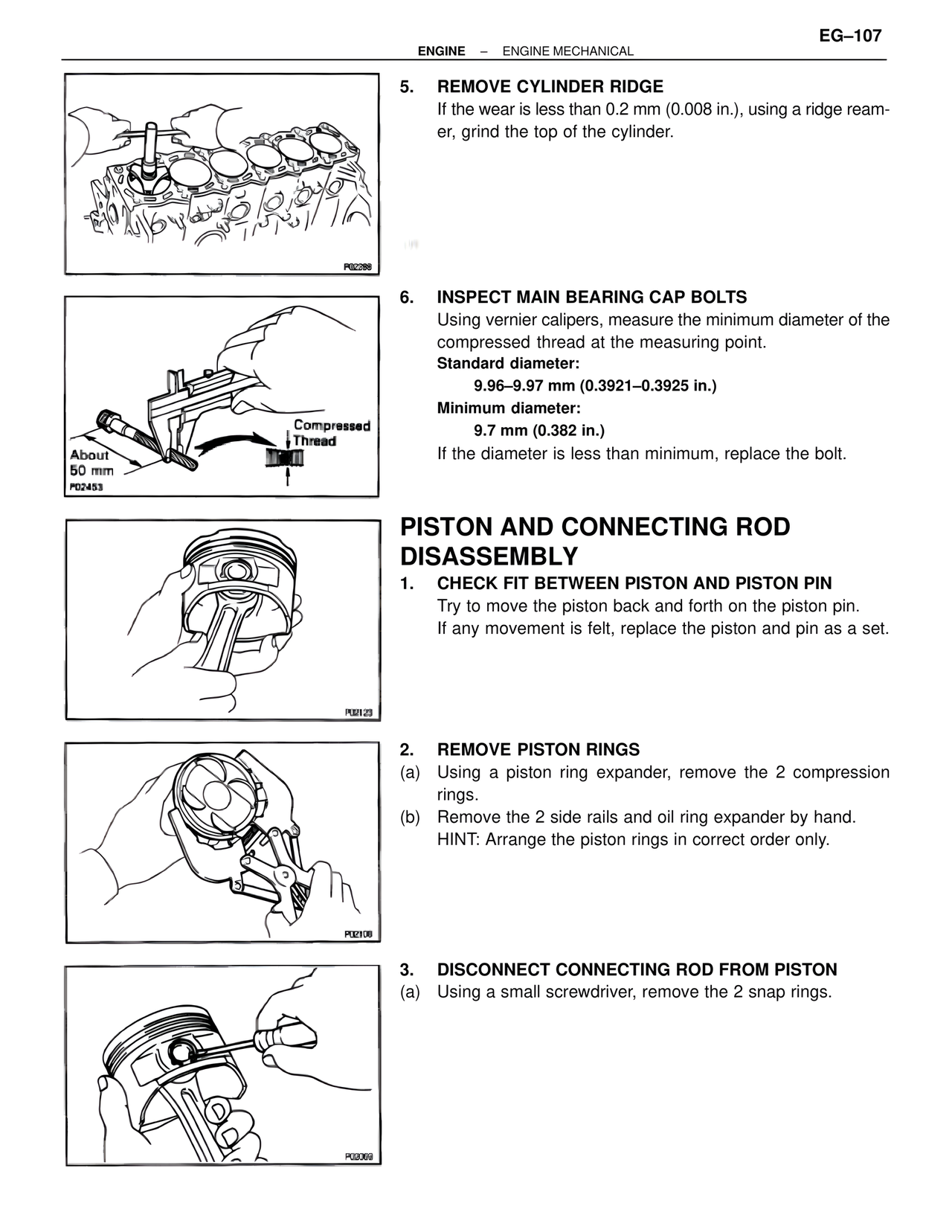

6. INSPECT MAIN BEARING CAP BOLTS

Using vernier calipers, measure the minimum diameter of the compressed thread at the measuring point.

Standard diameter:

9.96–9.97 mm (0.3921–0.3925 in.)

Minimum diameter:

9.7 mm (0.382 in.)

If the diameter is less than minimum, replace the bolt.

Compressed Thread

About 50 mm

P02453

PISTON AND CONNECTING ROD DISASSEMBLY

1. CHECK FIT BETWEEN PISTON AND PISTON PIN

Try to move the piston back and forth on the piston pin.

If any movement is felt, replace the piston and pin as a set.

P02123

2. REMOVE PISTON RINGS

(a) Using a piston ring expander, remove the 2 compression rings.

(b) Remove the 2 side rails and oil ring expander by hand.

HINT: Arrange the piston rings in correct order only.

P02106

3. DISCONNECT CONNECTING ROD FROM PISTON

(a) Using a small screwdriver, remove the 2 snap rings.

P02059