ENGINE – ENGINE MECHANICAL

EG–109

2. INSPECT PISTON

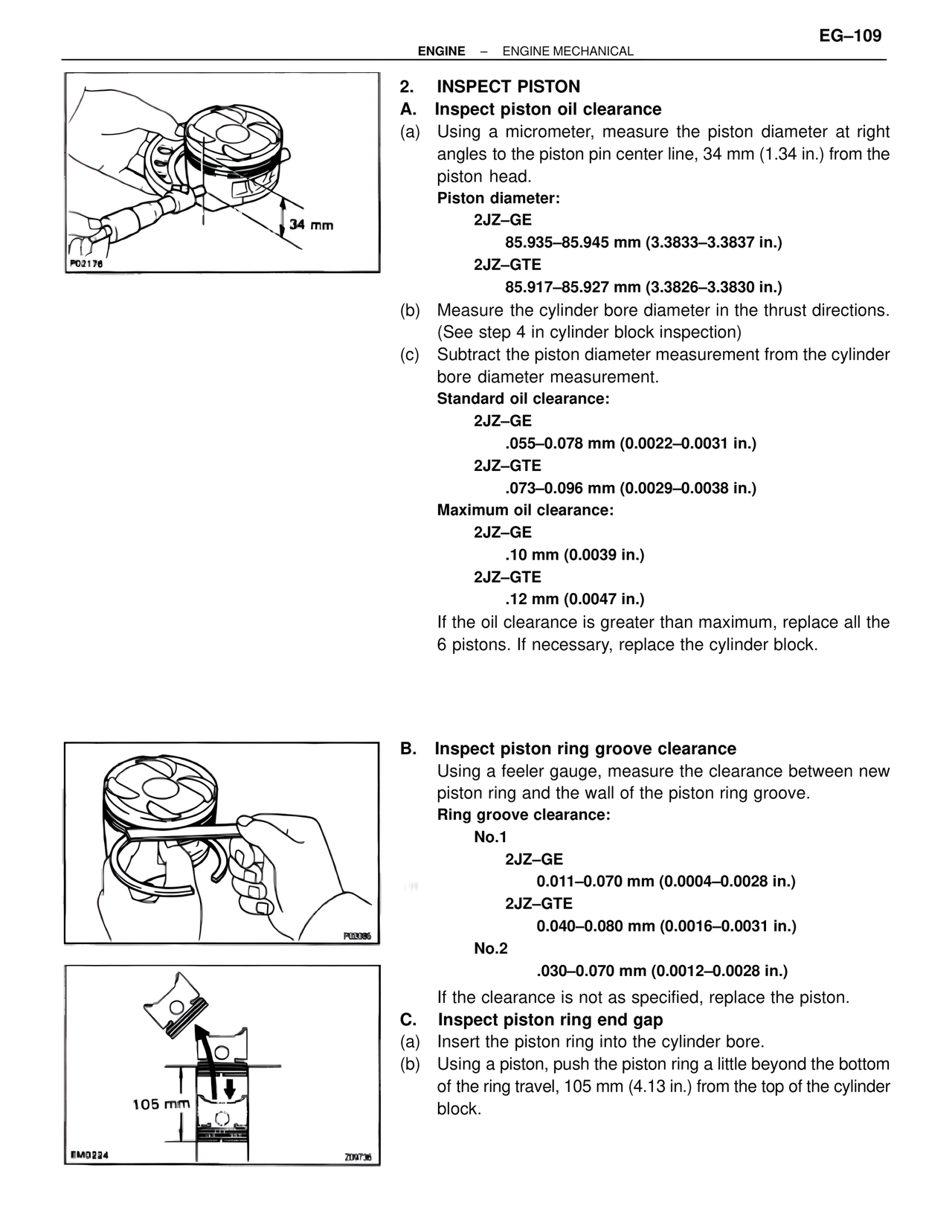

A. Inspect piston oil clearance

(a) Using a micrometer, measure the piston diameter at right

angles to the piston pin center line, 34 mm (1.34 in.) from the

piston head.

Piston diameter:

2JZ–GE

85.935–85.945 mm (3.3833–3.3837 in.)

2JZ–GTE

85.917–85.927 mm (3.3826–3.3830 in.)

(b) Measure the cylinder bore diameter in the thrust directions.

(See step 4 in cylinder block inspection)

(c) Subtract the piston diameter measurement from the cylinder

bore diameter measurement.

Standard oil clearance:

2JZ–GE

.055–0.078 mm (0.0022–0.0031 in.)

2JZ–GTE

.073–0.096 mm (0.0029–0.0038 in.)

Maximum oil clearance:

2JZ–GE

.10 mm (0.0039 in.)

2JZ–GTE

.12 mm (0.0047 in.)

If the oil clearance is greater than maximum, replace all the

6 pistons. If necessary, replace the cylinder block.

P02176

34 mm

B. Inspect piston ring groove clearance

Using a feeler gauge, measure the clearance between new

piston ring and the wall of the piston ring groove.

Ring groove clearance:

No.1

2JZ–GE

0.011–0.070 mm (0.0004–0.0028 in.)

2JZ–GTE

0.040–0.080 mm (0.0016–0.0031 in.)

No.2

.030–0.070 mm (0.0012–0.0028 in.)

If the clearance is not as specified, replace the piston.

C. Inspect piston ring end gap

(a) Insert the piston ring into the cylinder bore.

(b) Using a piston, push the piston ring a little beyond the bottom

of the ring travel, 105 mm (4.13 in.) from the top of the cylinder

block.

P02086

EM0224

105 mm

Z09736