ENGINE – ENGINE MECHANICAL

EG–113

CRANKSHAFT INSPECTION

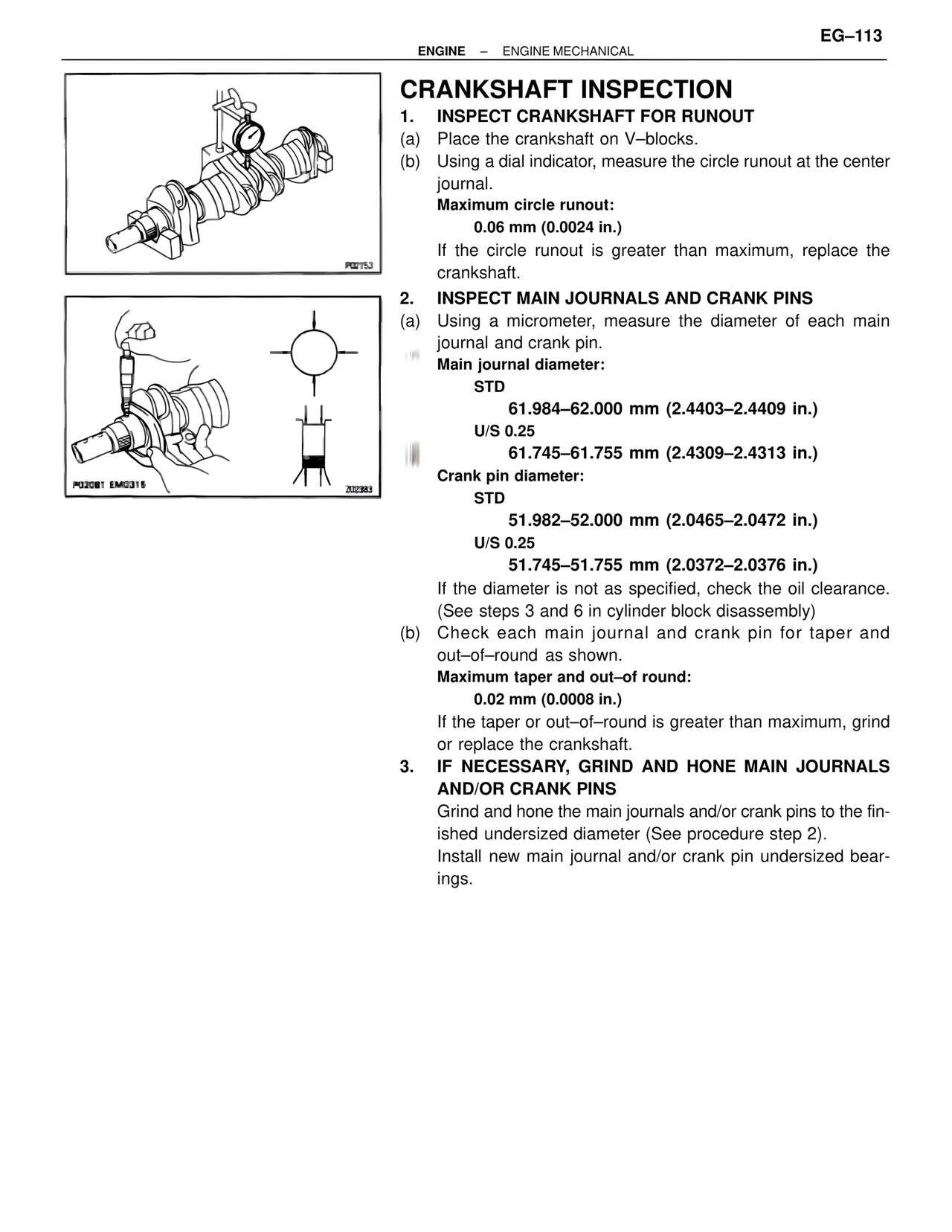

1. INSPECT CRANKSHAFT FOR RUNOUT

(a) Place the crankshaft on V–blocks.

(b) Using a dial indicator, measure the circle runout at the center journal.

Maximum circle runout:

0.06 mm (0.0024 in.)

If the circle runout is greater than maximum, replace the crankshaft.

2. INSPECT MAIN JOURNALS AND CRANK PINS

(a) Using a micrometer, measure the diameter of each main journal and crank pin.

Main journal diameter:

STD

61.984–62.000 mm (2.4403–2.4409 in.)

U/S 0.25

61.745–61.755 mm (2.4309–2.4313 in.)

Crank pin diameter:

STD

51.982–52.000 mm (2.0465–2.0472 in.)

U/S 0.25

51.745–51.755 mm (2.0372–2.0376 in.)

If the diameter is not as specified, check the oil clearance.

(See steps 3 and 6 in cylinder block disassembly)

(b) Check each main journal and crank pin for taper and out–of–round as shown.

Maximum taper and out–of round:

0.02 mm (0.0008 in.)

If the taper or out–of–round is greater than maximum, grind or replace the crankshaft.

3. IF NECESSARY, GRIND AND HONE MAIN JOURNALS AND/OR CRANK PINS

Grind and hone the main journals and/or crank pins to the finished undersized diameter (See procedure step 2).

Install new main journal and/or crank pin undersized bearings.

P02153

P02081 EM0315

Z02383