EG–122

ENGINE – ENGINE MECHANICAL

8. INSTALL FUEL PIPE SUPPORT

Torque: 14 N·m (145 kgf·cm, 10 ft·lbf)

9. INSTALL LH ENGINE MOUNTING BRACKET AND INSULATOR ASSEMBLY

HINT: LH mounting bracket is marked "A ← IN".

Torque: 58 N·m (590 kgf·cm, 43 ft·lbf)

10. INSTALL OIL FILTER BRACKET

(a) Check and clean the oil filter bracket installation.

(b) Place a new O–ring in position on the oil filter bracket.

(c) Apply clean engine oil to the O–ring.

(d) Install a new gasket to the union bolt.

(e) Install the oil filter braket with the union bolt.

Torque: 88 N·m (900 kgf·cm, 65 ft·lbf)

11. INSTALL NO.2 WATER BYPASS PIPE

(a) Install a new gasket to the water pump.

(b) 2JZ–GE:

Install the water bypass pipe with the bolt and 2 nuts.

Torque: 21 N·m (210 kgf·cm, 15 ft·lbf)

(c) 2JZ–GTE:

Install the water bypass pipe with the 2 bolts and 2 nuts.

Torque: 21 N·m (210 kgf·cm, 15 ft·lbf)

12. 2JZ–GTE:

INSTALL OIL COOLER

(See oil cooler installation in Lubrication System)

13. INSTALL OIL FILTER

(See oil and filter replacement in Lubrication System)

14. INSTALL CYLINDER HEAD

(See cylinder head installation)

15. INSTALL TIMING PULLEYS AND BELT

(See timing belt installation)

16. INSTALL GENERATOR

(See generator installation in Charging System)

17. REMOVE ENGINE STAND FROM ENGINE

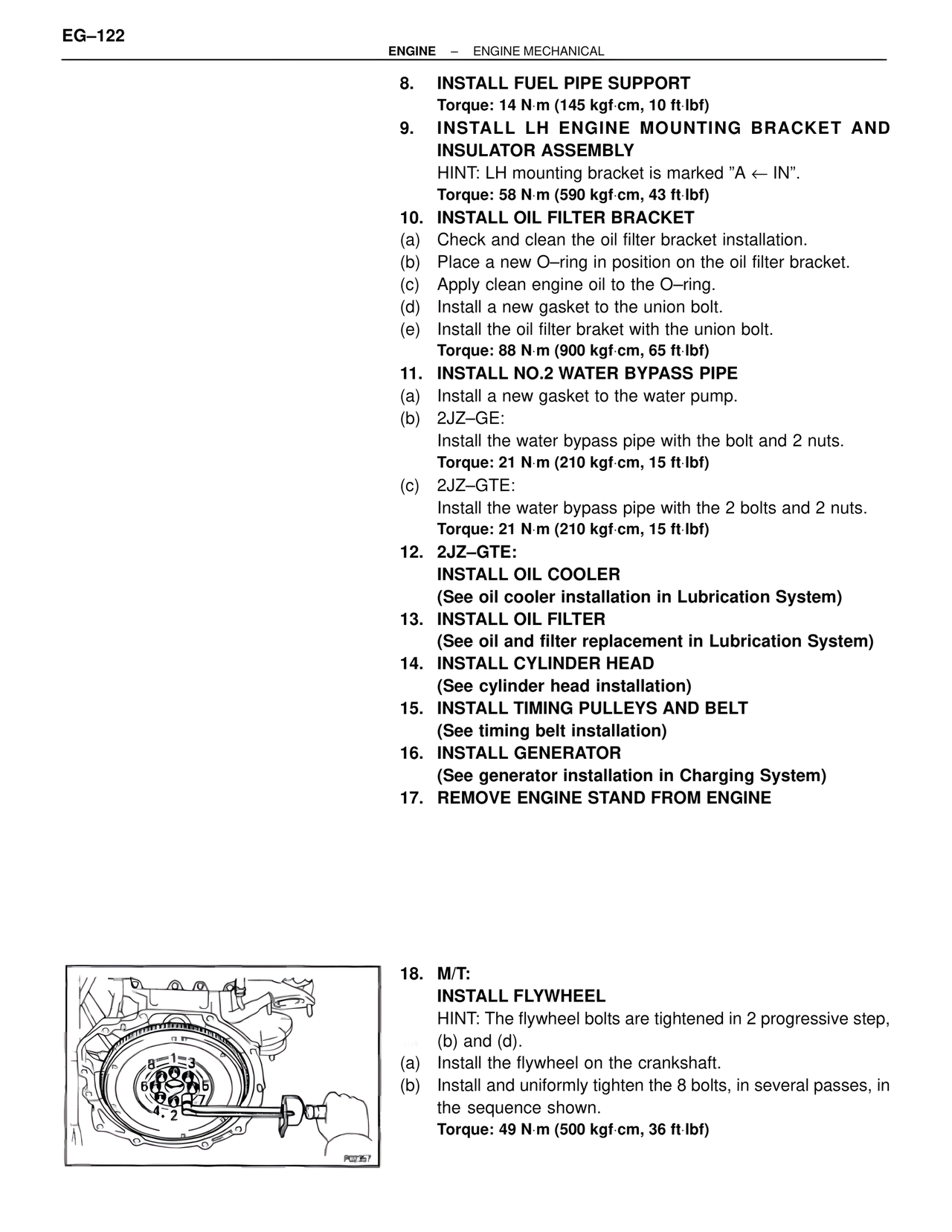

18. M/T:

INSTALL FLYWHEEL

HINT: The flywheel bolts are tightened in 2 progressive step, (b) and (d).

(a) Install the flywheel on the crankshaft.

(b) Install and uniformly tighten the 8 bolts, in several passes, in the sequence shown.

Torque: 49 N·m (500 kgf·cm, 36 ft·lbf)

P02357