EG–362

ENGINE – LUBRICATION SYSTEM

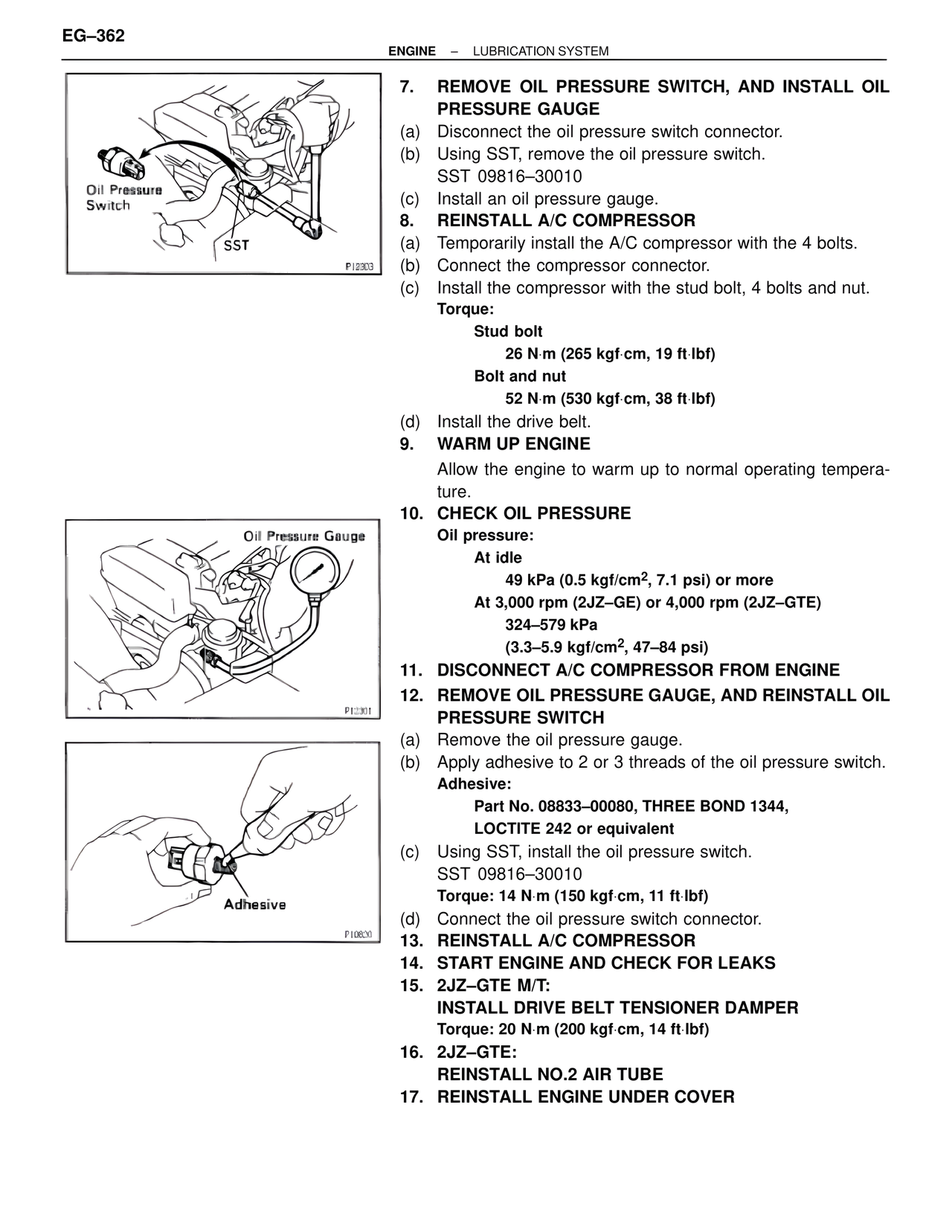

Oil Pressure

Switch

SST

P12303

7. REMOVE OIL PRESSURE SWITCH, AND INSTALL OIL

PRESSURE GAUGE

(a) Disconnect the oil pressure switch connector.

(b) Using SST, remove the oil pressure switch.

SST 09816–30010

(c) Install an oil pressure gauge.

8. REINSTALL A/C COMPRESSOR

(a) Temporarily install the A/C compressor with the 4 bolts.

(b) Connect the compressor connector.

(c) Install the compressor with the stud bolt, 4 bolts and nut.

Torque:

Stud bolt

26 N·m (265 kgf·cm, 19 ft·lbf)

Bolt and nut

52 N·m (530 kgf·cm, 38 ft·lbf)

(d) Install the drive belt.

9. WARM UP ENGINE

Allow the engine to warm up to normal operating tempera-

ture.

Oil Pressure Gauge

P12301

10. CHECK OIL PRESSURE

Oil pressure:

At idle

49 kPa (0.5 kgf/cm2, 7.1 psi) or more

At 3,000 rpm (2JZ–GE) or 4,000 rpm (2JZ–GTE)

324–579 kPa

(3.3–5.9 kgf/cm2, 47–84 psi)

11. DISCONNECT A/C COMPRESSOR FROM ENGINE

12. REMOVE OIL PRESSURE GAUGE, AND REINSTALL OIL

PRESSURE SWITCH

(a) Remove the oil pressure gauge.

(b) Apply adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive:

Part No. 08833–00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(c) Using SST, install the oil pressure switch.

SST 09816–30010

Torque: 14 N·m (150 kgf·cm, 11 ft·lbf)

(d) Connect the oil pressure switch connector.

13. REINSTALL A/C COMPRESSOR

14. START ENGINE AND CHECK FOR LEAKS

15. 2JZ–GTE M/T:

INSTALL DRIVE BELT TENSIONER DAMPER

Torque: 20 N·m (200 kgf·cm, 14 ft·lbf)

16. 2JZ–GTE:

REINSTALL NO.2 AIR TUBE

17. REINSTALL ENGINE UNDER COVER

Adhesive

P10820