SA–31

SUSPENSION AND AXLE – FRONT SUSPENSION

(b) Remove the nut, 2 bolts and the front lower arm bracket stay.

Torque:

Bolt: 44 N·m (450 kgf·cm, 33 ft·lbf)

Nut: 59 N·m (600 kgf·cm, 43 ft·lbf)

INSTALLATION HINT: Before installing the lower arm bracket stay, adjust front wheel alignment.

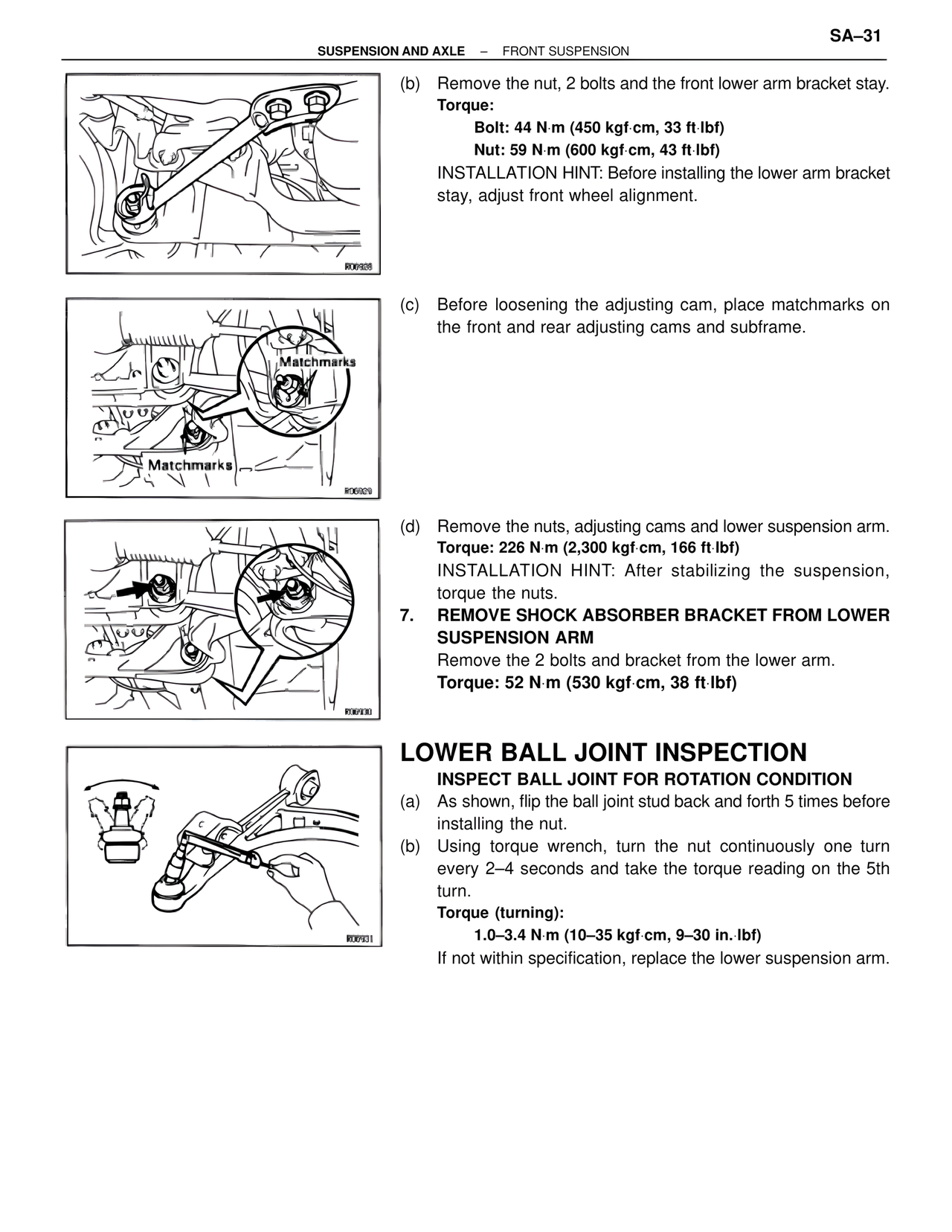

(c) Before loosening the adjusting cam, place matchmarks on the front and rear adjusting cams and subframe.

Matchmarks

Matchmarks

(d) Remove the nuts, adjusting cams and lower suspension arm.

Torque: 226 N·m (2,300 kgf·cm, 166 ft·lbf)

INSTALLATION HINT: After stabilizing the suspension, torque the nuts.

7. REMOVE SHOCK ABSORBER BRACKET FROM LOWER SUSPENSION ARM

Remove the 2 bolts and bracket from the lower arm.

Torque: 52 N·m (530 kgf·cm, 38 ft·lbf)

LOWER BALL JOINT INSPECTION

INSPECT BALL JOINT FOR ROTATION CONDITION

(a) As shown, flip the ball joint stud back and forth 5 times before installing the nut.

(b) Using torque wrench, turn the nut continuously one turn every 2–4 seconds and take the torque reading on the 5th turn.

Torque (turning):

1.0–3.4 N·m (10–35 kgf·cm, 9–30 in.·lbf)

If not within specification, replace the lower suspension arm.