SA–71

SUSPENSION AND AXLE – REAR DIFFERENTIAL

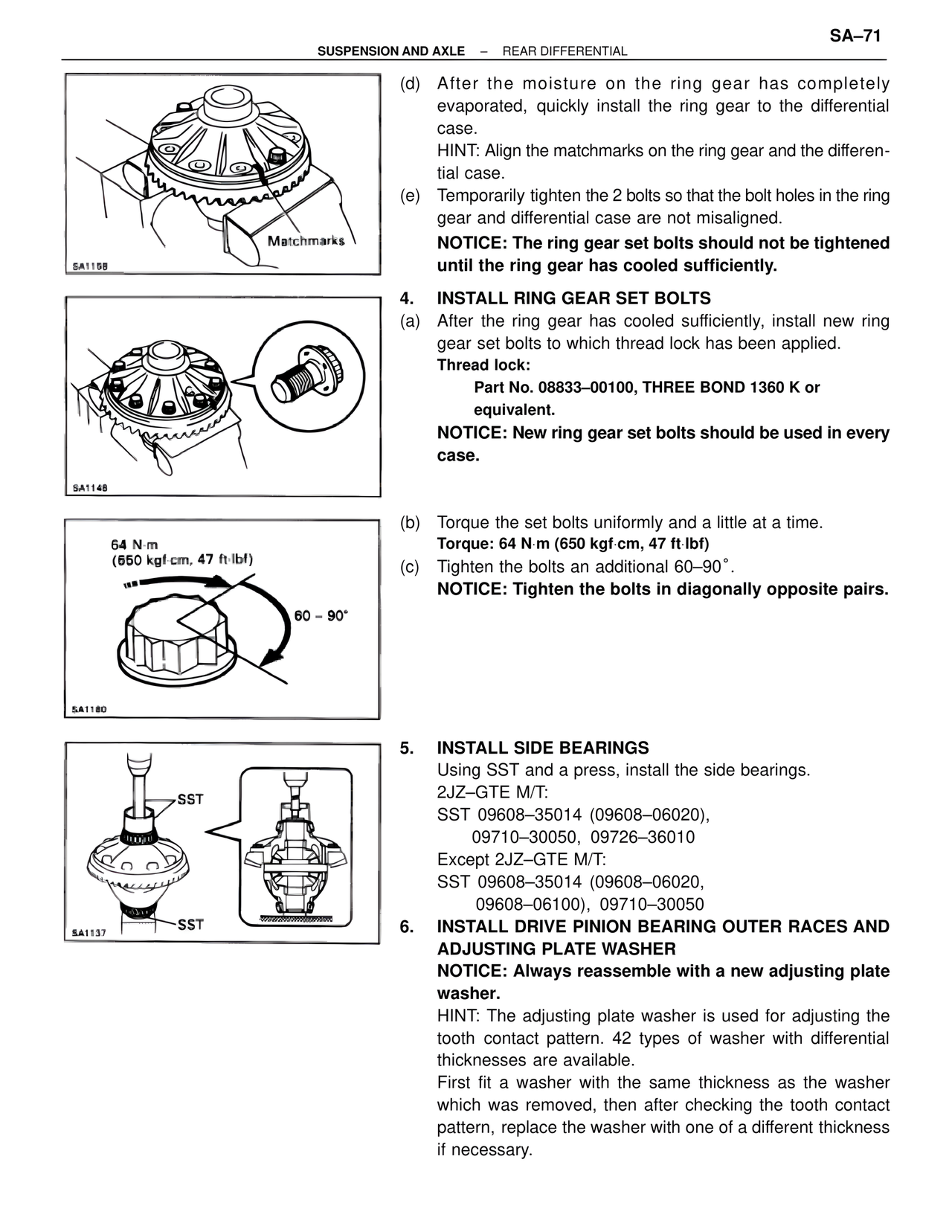

Matchmarks

SA1158

(d) After the moisture on the ring gear has completely

evaporated, quickly install the ring gear to the differential

case.

HINT: Align the matchmarks on the ring gear and the differen-

tial case.

(e) Temporarily tighten the 2 bolts so that the bolt holes in the ring

gear and differential case are not misaligned.

NOTICE: The ring gear set bolts should not be tightened

until the ring gear has cooled sufficiently.

SA1148

4. INSTALL RING GEAR SET BOLTS

(a) After the ring gear has cooled sufficiently, install new ring

gear set bolts to which thread lock has been applied.

Thread lock:

Part No. 08833–00100, THREE BOND 1360 K or

equivalent.

NOTICE: New ring gear set bolts should be used in every

case.

64 N·m

(650 kgf·cm, 47 ft·lbf)

60 – 90°

SA1180

(b) Torque the set bolts uniformly and a little at a time.

Torque: 64 N·m (650 kgf·cm, 47 ft·lbf)

(c) Tighten the bolts an additional 60–90°.

NOTICE: Tighten the bolts in diagonally opposite pairs.

SST

SST

SA1137

5. INSTALL SIDE BEARINGS

Using SST and a press, install the side bearings.

2JZ–GTE M/T:

SST 09608–35014 (09608–06020),

09710–30050, 09726–36010

Except 2JZ–GTE M/T:

SST 09608–35014 (09608–06020,

09608–06100), 09710–30050

6. INSTALL DRIVE PINION BEARING OUTER RACES AND

ADJUSTING PLATE WASHER

NOTICE: Always reassemble with a new adjusting plate

washer.

HINT: The adjusting plate washer is used for adjusting the

tooth contact pattern. 42 types of washer with differential

thicknesses are available.

First fit a washer with the same thickness as the washer

which was removed, then after checking the tooth contact

pattern, replace the washer with one of a different thickness

if necessary.