SA–70

SUSPENSION AND AXLE – REAR DIFFERENTIAL

DIFFERENTIAL CARRIER ASSEMBLY

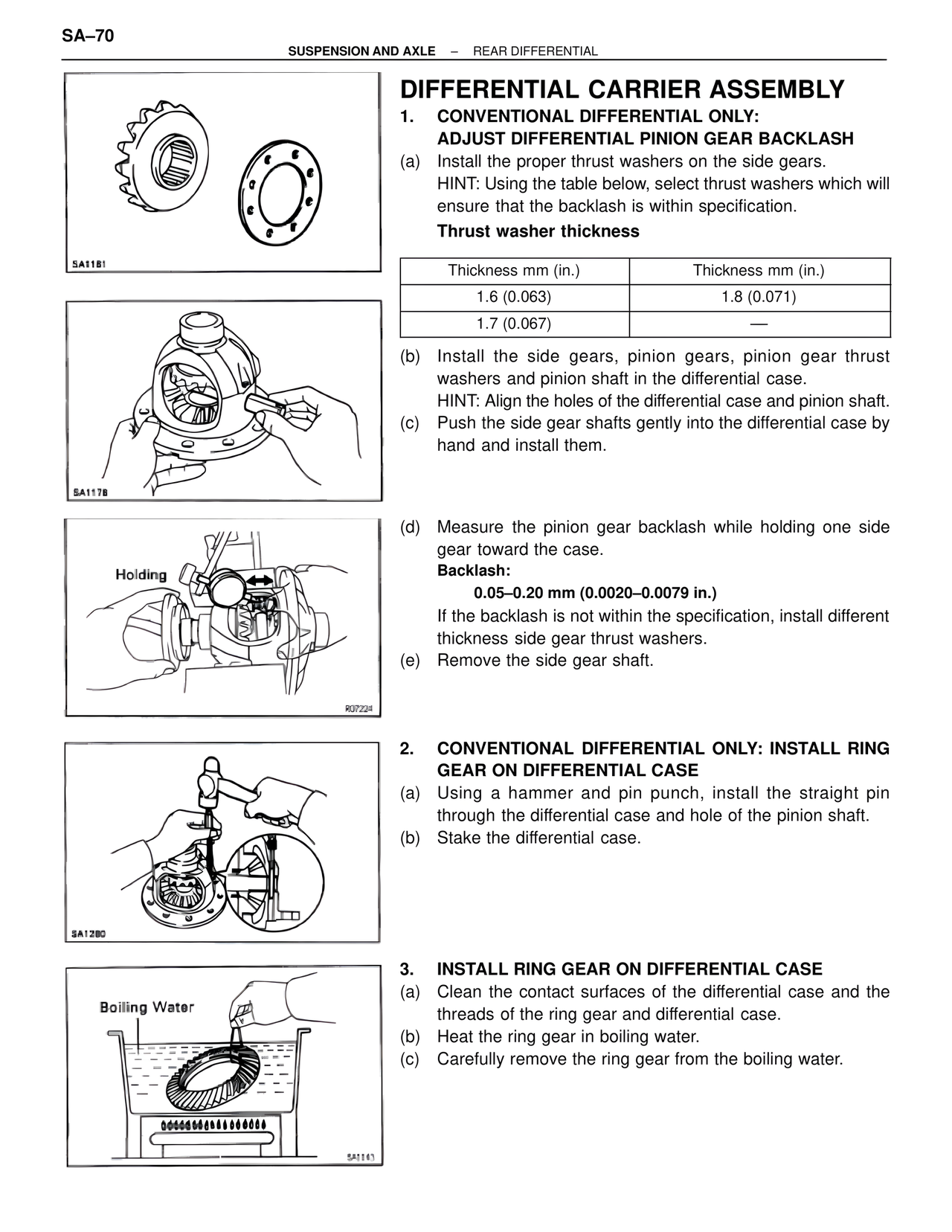

1. CONVENTIONAL DIFFERENTIAL ONLY:

ADJUST DIFFERENTIAL PINION GEAR BACKLASH

(a) Install the proper thrust washers on the side gears.

HINT: Using the table below, select thrust washers which will

ensure that the backlash is within specification.

Thrust washer thickness

Thickness mm (in.) | Thickness mm (in.)

1.6 (0.063) | 1.8 (0.071)

1.7 (0.067) | —

(b) Install the side gears, pinion gears, pinion gear thrust

washers and pinion shaft in the differential case.

HINT: Align the holes of the differential case and pinion shaft.

(c) Push the side gear shafts gently into the differential case by

hand and install them.

(d) Measure the pinion gear backlash while holding one side

gear toward the case.

Backlash:

0.05–0.20 mm (0.0020–0.0079 in.)

If the backlash is not within the specification, install different

thickness side gear thrust washers.

(e) Remove the side gear shaft.

2. CONVENTIONAL DIFFERENTIAL ONLY: INSTALL RING

GEAR ON DIFFERENTIAL CASE

(a) Using a hammer and pin punch, install the straight pin

through the differential case and hole of the pinion shaft.

(b) Stake the differential case.

3. INSTALL RING GEAR ON DIFFERENTIAL CASE

(a) Clean the contact surfaces of the differential case and the

threads of the ring gear and differential case.

(b) Heat the ring gear in boiling water.

(c) Carefully remove the ring gear from the boiling water.

SA1181

SA117B

R07224

SA1280

Holding

Boiling Water

SA1141