EG–315

ENGINE – SFI SYSTEM (2JZ–GTE)

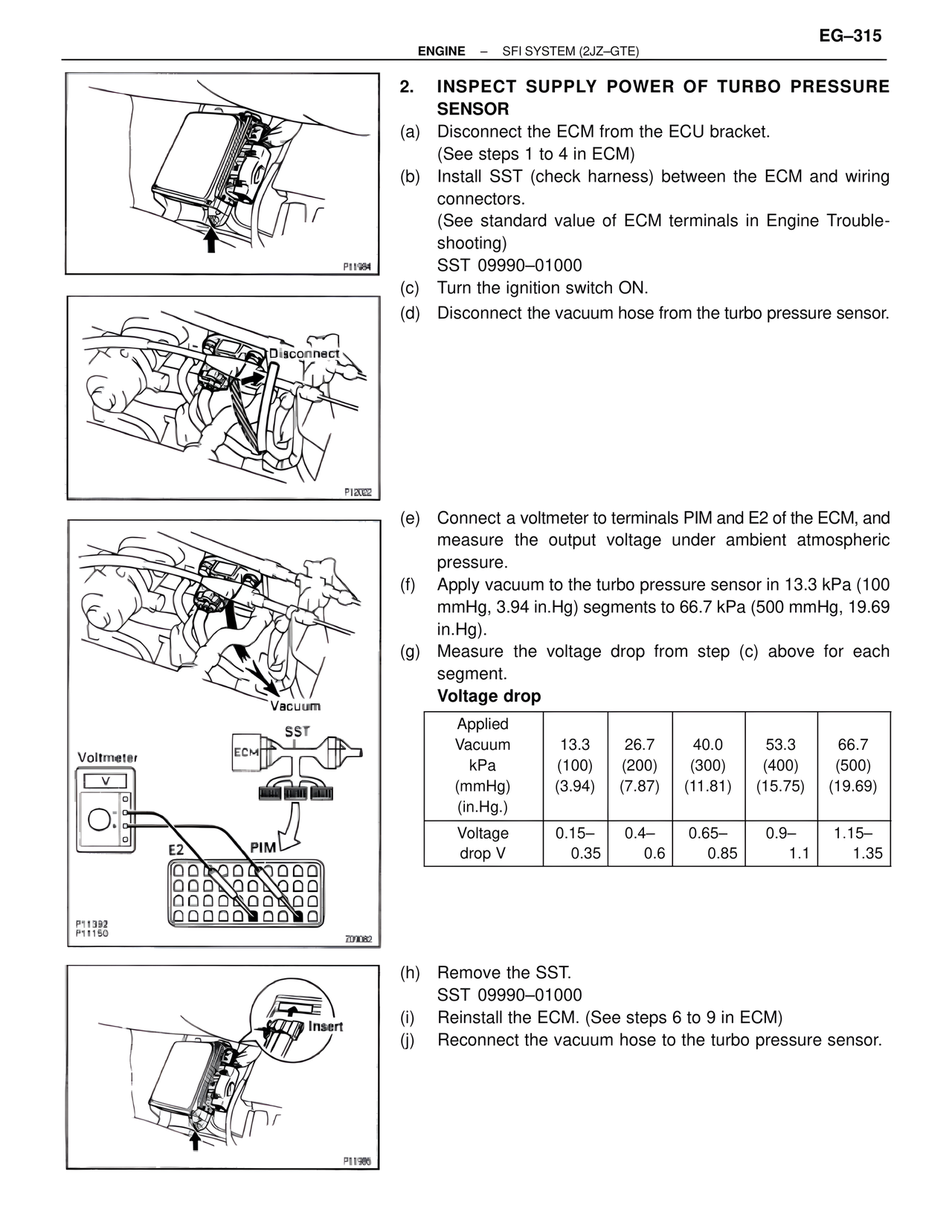

2. INSPECT SUPPLY POWER OF TURBO PRESSURE SENSOR

(a) Disconnect the ECM from the ECU bracket.

(See steps 1 to 4 in ECM)

(b) Install SST (check harness) between the ECM and wiring connectors.

(See standard value of ECM terminals in Engine Troubleshooting)

SST 09990–01000

(c) Turn the ignition switch ON.

(d) Disconnect the vacuum hose from the turbo pressure sensor.

Disconnect

(e) Connect a voltmeter to terminals PIM and E2 of the ECM, and measure the output voltage under ambient atmospheric pressure.

(f) Apply vacuum to the turbo pressure sensor in 13.3 kPa (100 mmHg, 3.94 in.Hg) segments to 66.7 kPa (500 mmHg, 19.69 in.Hg).

(g) Measure the voltage drop from step (c) above for each segment.

Voltage drop

Applied Vacuum kPa (mmHg) (in.Hg.)

13.3 (100) (3.94)

26.7 (200) (7.87)

40.0 (300) (11.81)

53.3 (400) (15.75)

66.7 (500) (19.69)

Voltage drop V

0.15–0.35

0.4–0.6

0.65–0.85

0.9–1.1

1.15–1.35

Vacuum

SST

ECM

Voltmeter

E2 PIM

P11392

P11150

Z09082

(h) Remove the SST.

SST 09990–01000

(i) Reinstall the ECM. (See steps 6 to 9 in ECM)

(j) Reconnect the vacuum hose to the turbo pressure sensor.

Insert

P11984

P12022

P11386