EG–420

ENGINE – 2JZ–GE ENGINE TROUBLESHOOTING

CIRCUIT DESCRIPTION (Cont'd)

DIAGNOSTIC TROUBLE CODE DETECTION DRIVING PATTERN

Purpose of the driving pattern.

(a) To simulate diagnostic trouble code detecting condition after diagnostic trouble code is recorded.

(b) To check that the malfunction is corrected when the repair is completed confirming that diagnostic trouble code is no longer detected.

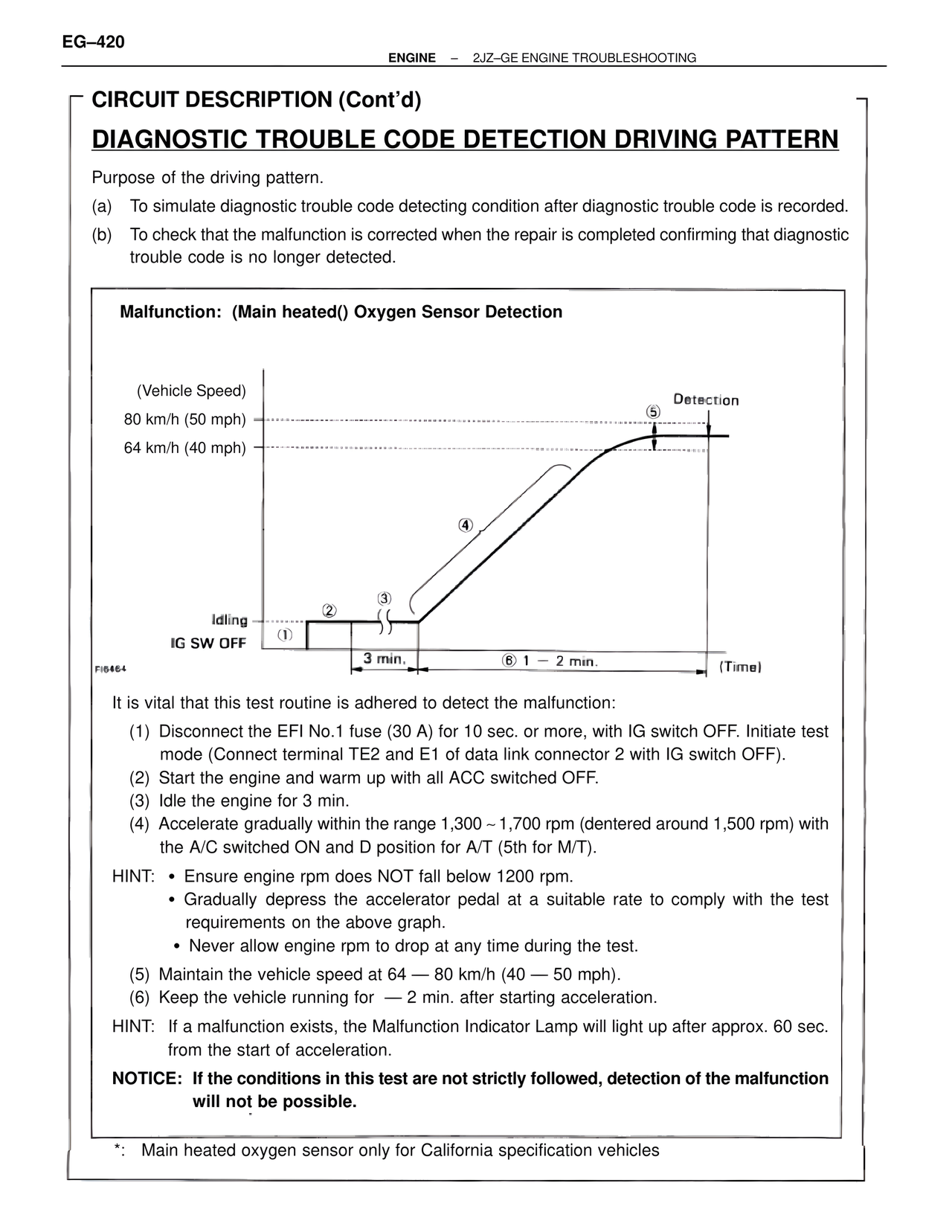

Malfunction: (Main heated() Oxygen Sensor Detection

(Vehicle Speed)

80 km/h (50 mph)

64 km/h (40 mph)

Detection

(5)

(4)

Idling

IG SW OFF

(1)

(2)

(3)

3 min.

(6) 1 – 2 min.

(Time)

FI6464

It is vital that this test routine is adhered to detect the malfunction:

(1) Disconnect the EFI No.1 fuse (30 A) for 10 sec. or more, with IG switch OFF. Initiate test mode (Connect terminal TE2 and E1 of data link connector 2 with IG switch OFF).

(2) Start the engine and warm up with all ACC switched OFF.

(3) Idle the engine for 3 min.

(4) Accelerate gradually within the range 1,300 ~ 1,700 rpm (dentered around 1,500 rpm) with the A/C switched ON and D position for A/T (5th for M/T).

HINT: • Ensure engine rpm does NOT fall below 1200 rpm.

• Gradually depress the accelerator pedal at a suitable rate to comply with the test requirements on the above graph.

• Never allow engine rpm to drop at any time during the test.

(5) Maintain the vehicle speed at 64 — 80 km/h (40 — 50 mph).

(6) Keep the vehicle running for — 2 min. after starting acceleration.

HINT: If a malfunction exists, the Malfunction Indicator Lamp will light up after approx. 60 sec. from the start of acceleration.

NOTICE: If the conditions in this test are not strictly followed, detection of the malfunction will not be possible.

*: Main heated oxygen sensor only for California specification vehicles