(l) Remove the lock nut.

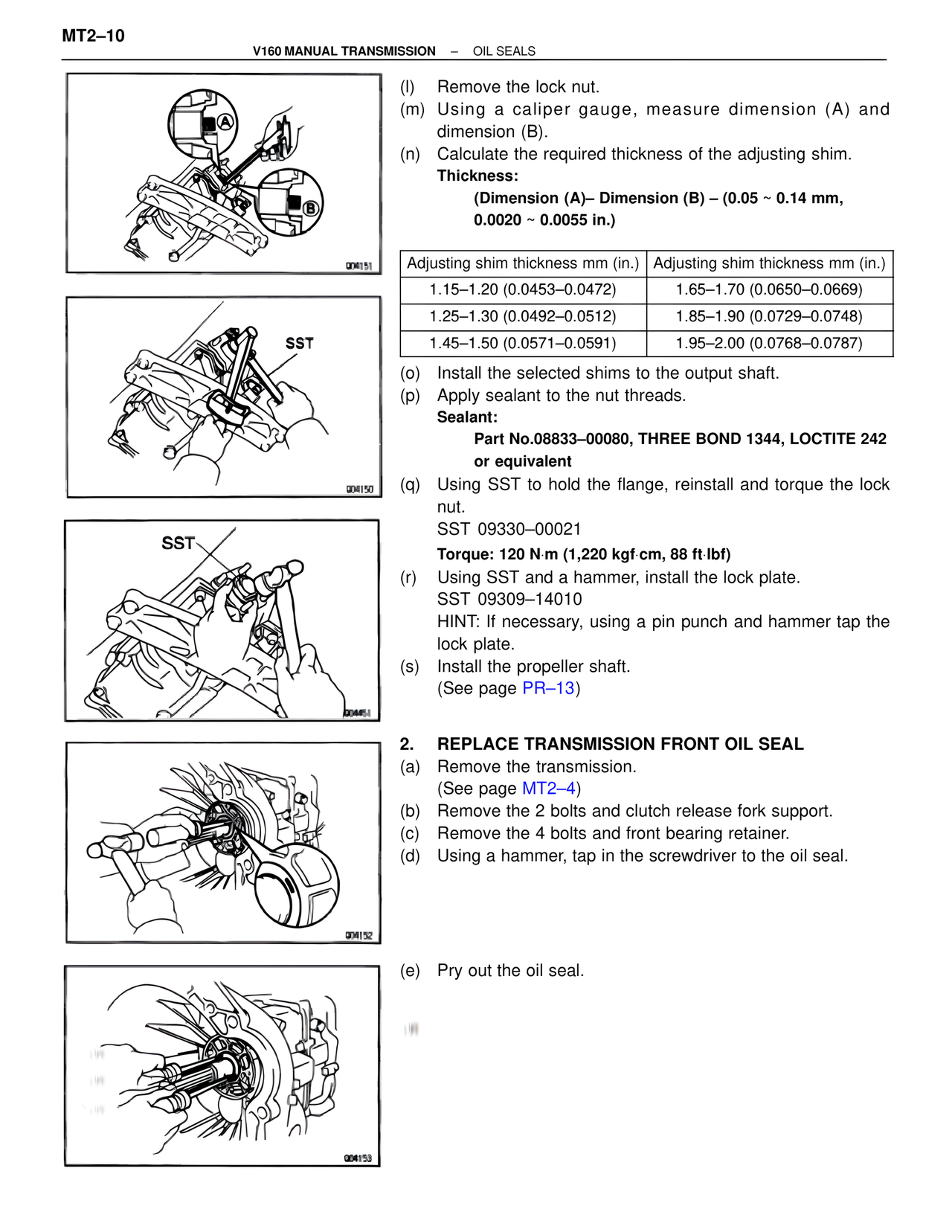

(m) Using a caliper gauge, measure dimension (A) and

dimension (B).

(n) Calculate the required thickness of the adjusting shim.

Thickness:

(Dimension (A)– Dimension (B) – (0.05 ~ 0.14 mm,

0.0020 ~ 0.0055 in.)

Adjusting shim thickness mm (in.) | Adjusting shim thickness mm (in.)

1.15–1.20 (0.0453–0.0472) | 1.65–1.70 (0.0650–0.0669)

1.25–1.30 (0.0492–0.0512) | 1.85–1.90 (0.0729–0.0748)

1.45–1.50 (0.0571–0.0591) | 1.95–2.00 (0.0768–0.0787)

(o) Install the selected shims to the output shaft.

(p) Apply sealant to the nut threads.

Sealant:

Part No.08833–00080, THREE BOND 1344, LOCTITE 242

or equivalent

(q) Using SST to hold the flange, reinstall and torque the lock

nut.

SST 09330–00021

Torque: 120 N·m (1,220 kgf·cm, 88 ft·lbf)

(r) Using SST and a hammer, install the lock plate.

SST 09309–14010

HINT: If necessary, using a pin punch and hammer tap the

lock plate.

(s) Install the propeller shaft.

(See page PR–13)

2. REPLACE TRANSMISSION FRONT OIL SEAL

(a) Remove the transmission.

(See page MT2–4)

(b) Remove the 2 bolts and clutch release fork support.

(c) Remove the 4 bolts and front bearing retainer.

(d) Using a hammer, tap in the screwdriver to the oil seal.

(e) Pry out the oil seal.