(d) Using a feeler gauge, measure the clearance between the

synchronizer ring back and gear spline end.

Minimum clearance:

0.5 mm (0.020 in.)

HINT: When replacing either a synchronizer ring or gear, ap-

ply a small amount of fine lapping compound between the

synchronizer ring and gear cone.

Lightly rub the synchronizer ring and gear cone together.

NOTICE:

• When replacing both the synchronizer ring and gear,

there is no need to apply any compound or to rub them

together.

• Ensure the fine lapping compound is completely washed

off after rubbing.

2. INSPECT 2 ND AND 3 RD GEAR SYNCHRONIZER RINGS

(a) Check for wear or damage.

(b) Install the synchronizer inner ring, middle ring and outer ring

to each gear.

(c) Check the braking effect of the synchronizer ring.

Turn the synchronizer ring in one direction while pushing it to

the gear cone. Check that the ring locks.

If it does not lock, replace the synchronizer ring.

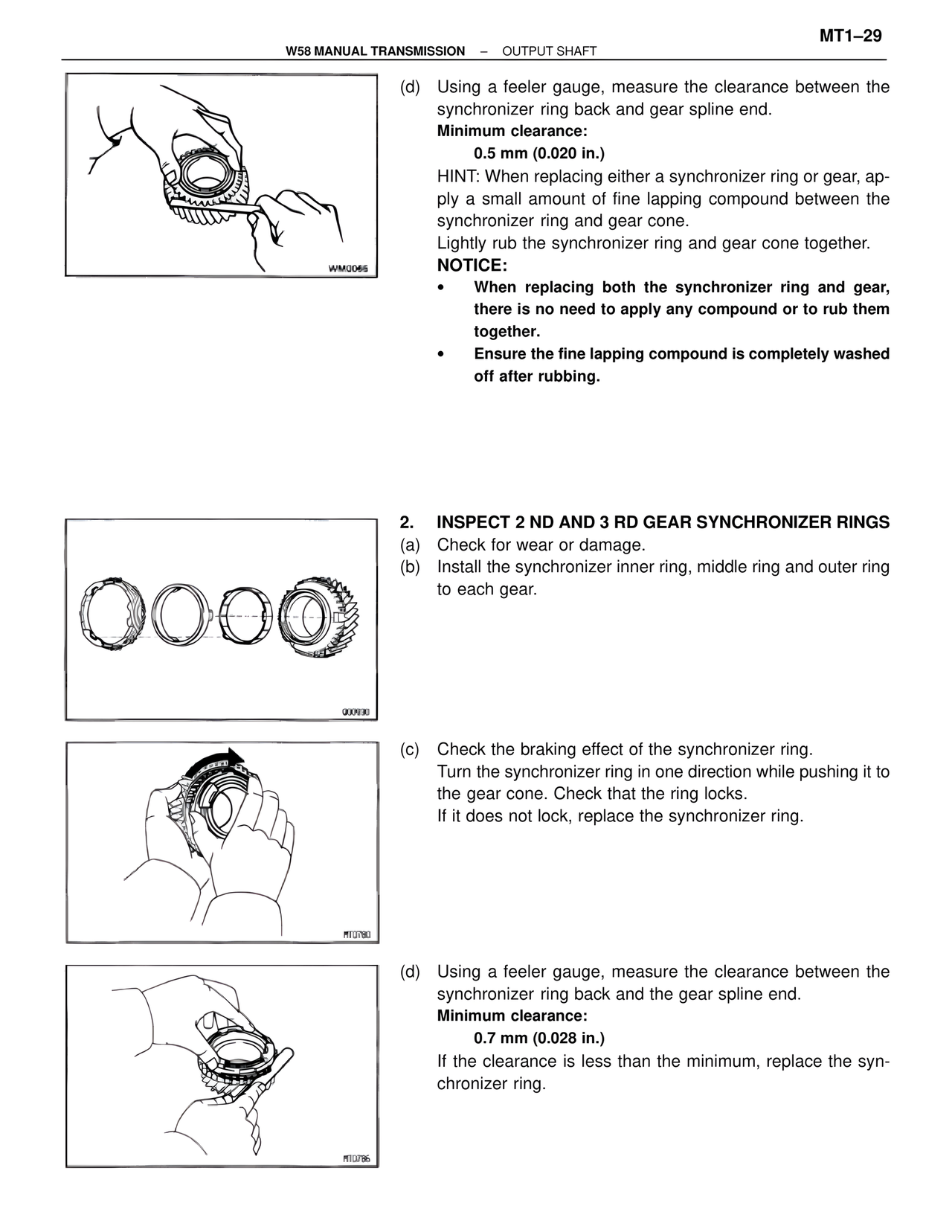

(d) Using a feeler gauge, measure the clearance between the

synchronizer ring back and the gear spline end.

Minimum clearance:

0.7 mm (0.028 in.)

If the clearance is less than the minimum, replace the syn-

chronizer ring.