G–3

APPENDIX–REPORTING OF WIRE HARNESS PROBLEM

WIRE HARNESS/CONNECTOR PROBLEM CHECK SHEET page 1/3

Please use the TOYOTA ELECTRICAL WIRING DIAGRAM (EWD) manual to answer this questionnaire accurately.

Dealer Name Dealer Code

Full Model Code Frame No.

P/D / km-reading/Mileage Date of Problem / /

Customer Complaint:

Electrical Component with Problem:

Condition: □ Intermittent operation □ Inoperative □ Others

Symptom: □ Short □ Open circuit □ Moisture

□ Others (Eg.Rattle,Noise etc. - Please proceed to "Box B" on next page.)

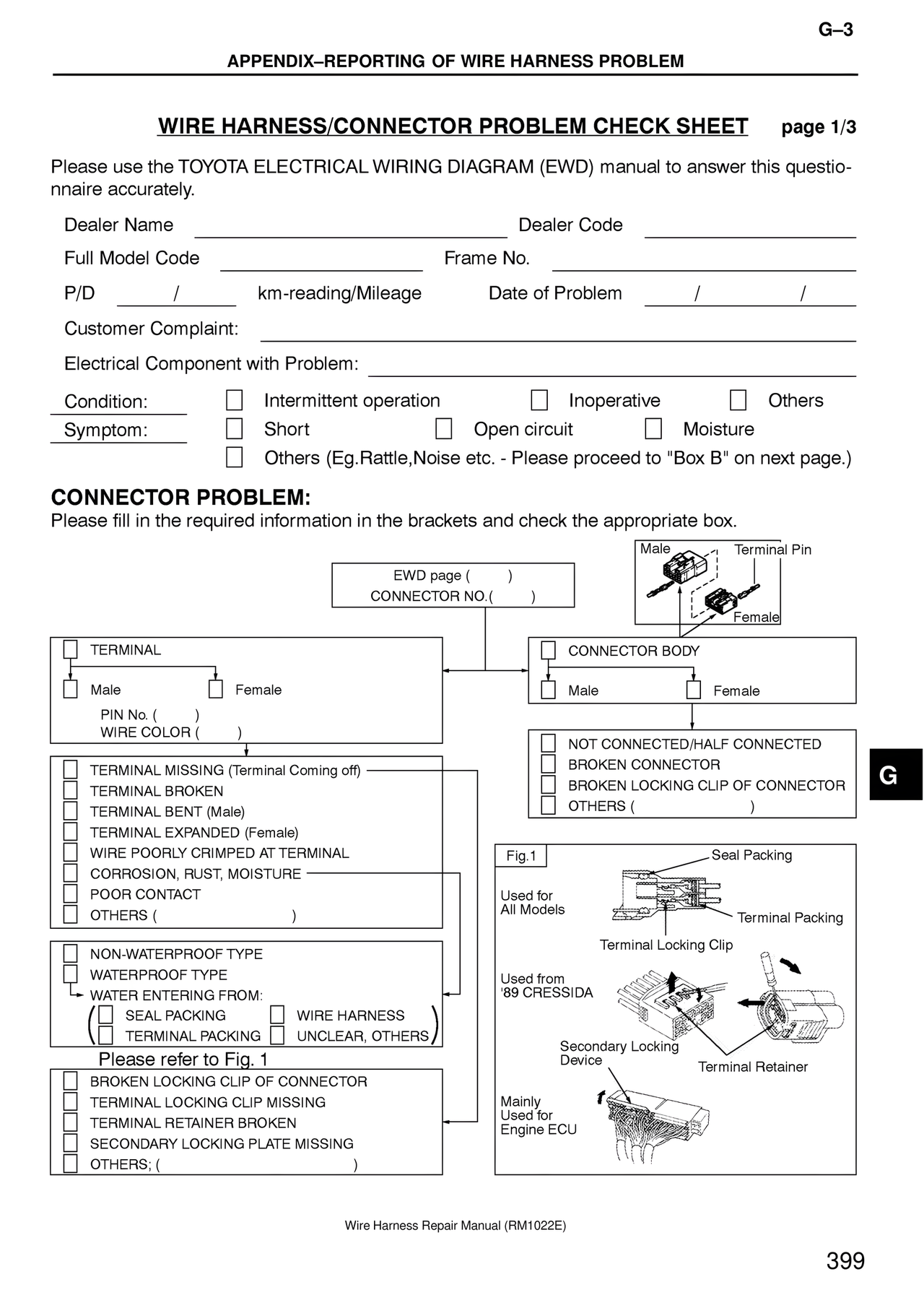

CONNECTOR PROBLEM:

Please fill in the required information in the brackets and check the appropriate box.

EWD page ( )

CONNECTOR NO.( )

Male Terminal Pin

Female

□ TERMINAL

□ Male □ Female

PIN No. ( )

WIRE COLOR ( )

□ CONNECTOR BODY

□ Male □ Female

□ TERMINAL MISSING (Terminal Coming off)

□ TERMINAL BROKEN

□ TERMINAL BENT (Male)

□ TERMINAL EXPANDED (Female)

□ WIRE POORLY CRIMPED AT TERMINAL

□ CORROSION, RUST, MOISTURE

□ POOR CONTACT

□ OTHERS ( )

□ NOT CONNECTED/HALF CONNECTED

□ BROKEN CONNECTOR

□ BROKEN LOCKING CLIP OF CONNECTOR

□ OTHERS ( )

Fig.1 Seal Packing

Used for

All Models Terminal Packing

Terminal Locking Clip

□ NON-WATERPROOF TYPE

□ WATERPROOF TYPE

→ WATER ENTERING FROM:

( □ SEAL PACKING □ WIRE HARNESS )

□ TERMINAL PACKING □ UNCLEAR, OTHERS

Please refer to Fig. 1

Used from

'89 CRESSIDA

Secondary Locking

Device Terminal Retainer

□ BROKEN LOCKING CLIP OF CONNECTOR

□ TERMINAL LOCKING CLIP MISSING

□ TERMINAL RETAINER BROKEN

□ SECONDARY LOCKING PLATE MISSING

□ OTHERS; ( )

Mainly

Used for

Engine ECU

G

Wire Harness Repair Manual (RM1022E)

399