CH–13

CHARGING SYSTEM – GENERATOR

GENERATOR INSPECTION AND REPAIR

Rotor

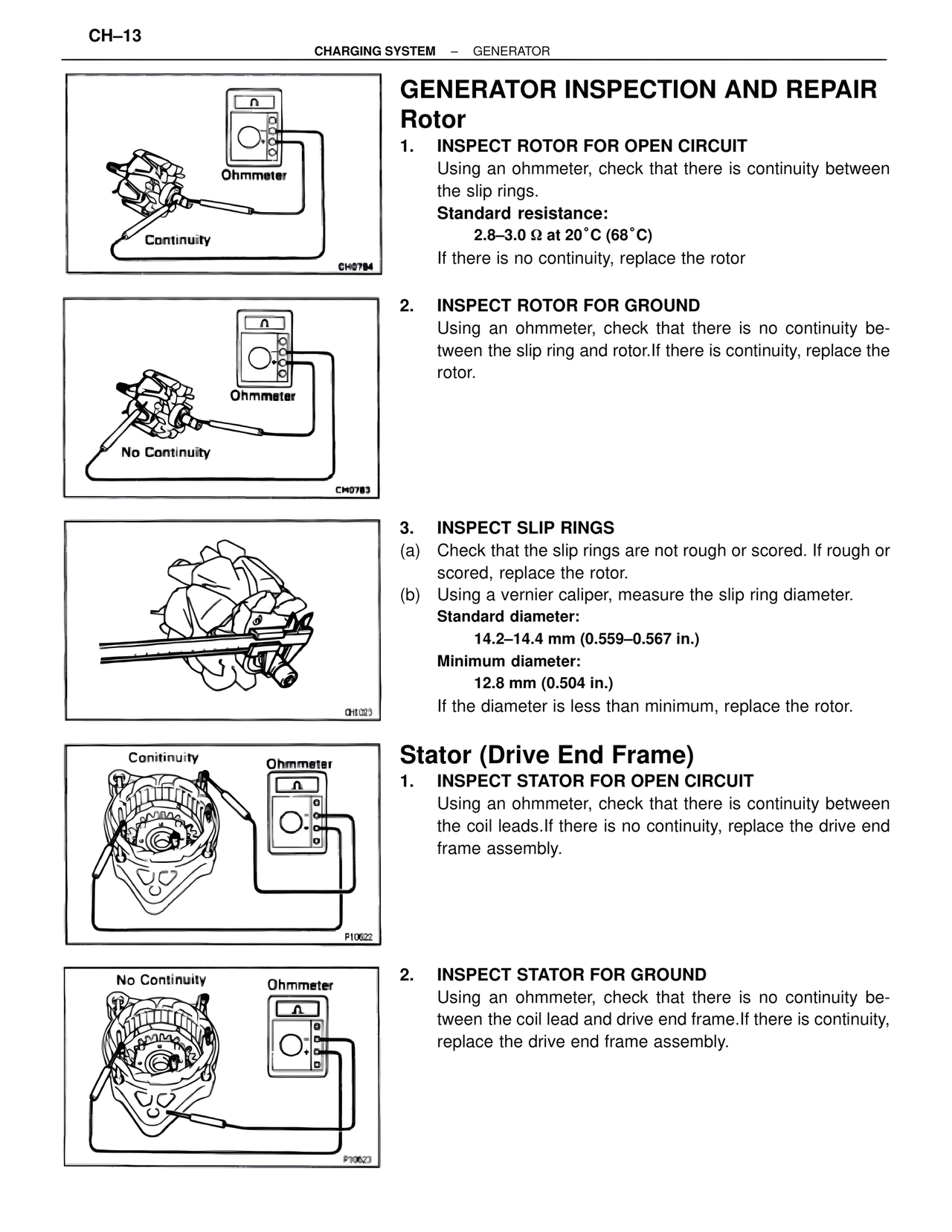

1. INSPECT ROTOR FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between

the slip rings.

Standard resistance:

2.8–3.0 Ω at 20˚C (68˚C)

If there is no continuity, replace the rotor

Continuity

Ohmmeter

CH0784

2. INSPECT ROTOR FOR GROUND

Using an ohmmeter, check that there is no continuity be-

tween the slip ring and rotor.If there is continuity, replace the

rotor.

Ohmmeter

No Continuity

CH0783

3. INSPECT SLIP RINGS

(a) Check that the slip rings are not rough or scored. If rough or

scored, replace the rotor.

(b) Using a vernier caliper, measure the slip ring diameter.

Standard diameter:

14.2–14.4 mm (0.559–0.567 in.)

Minimum diameter:

12.8 mm (0.504 in.)

If the diameter is less than minimum, replace the rotor.

CH1023

Stator (Drive End Frame)

1. INSPECT STATOR FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between

the coil leads.If there is no continuity, replace the drive end

frame assembly.

Conituinity

Ohmmeter

P10622

2. INSPECT STATOR FOR GROUND

Using an ohmmeter, check that there is no continuity be-

tween the coil lead and drive end frame.If there is continuity,

replace the drive end frame assembly.

No Continuity

Ohmmeter

P90623