Front

Painted

Mark

P02371

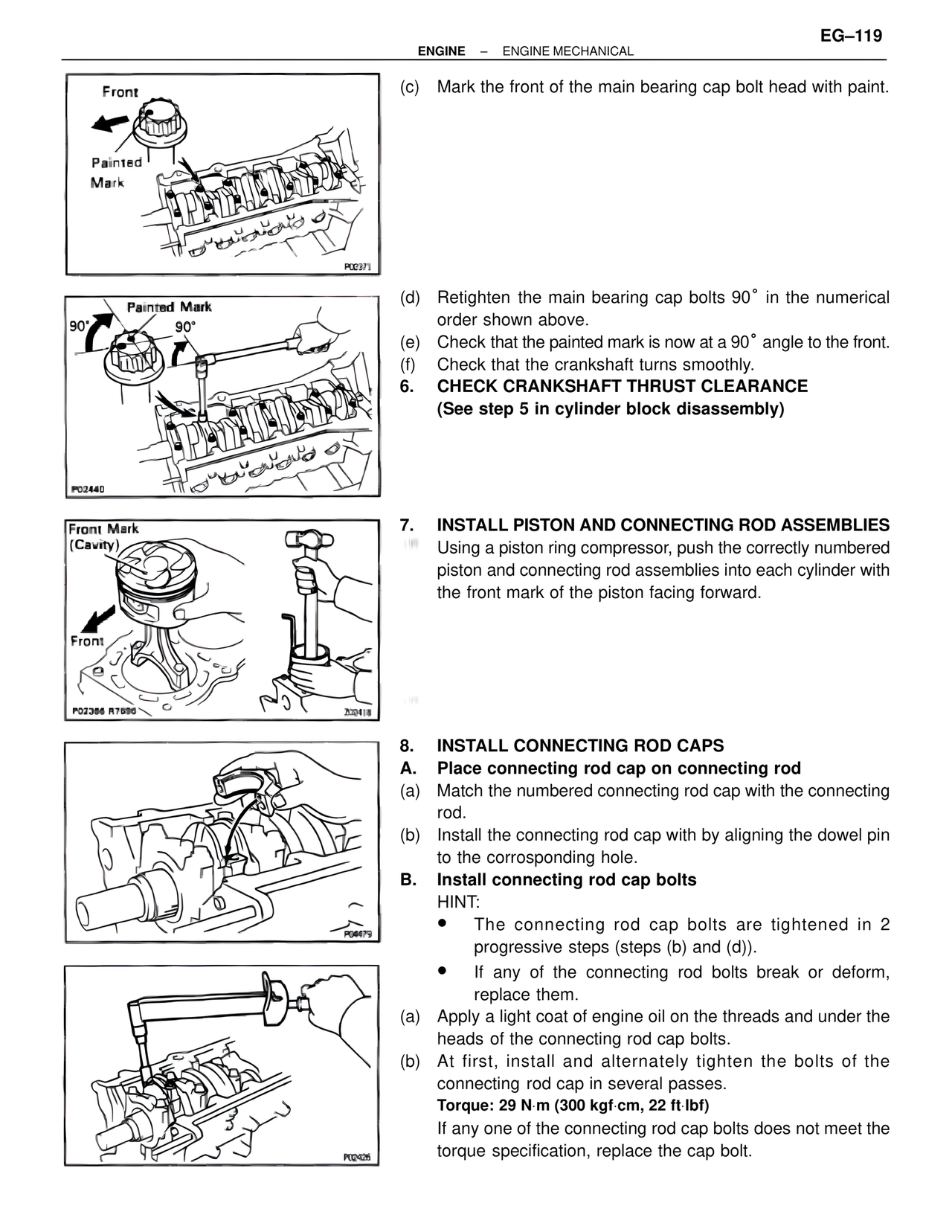

(c) Mark the front of the main bearing cap bolt head with paint.

Painted Mark

90°

90°

P02440

(d) Retighten the main bearing cap bolts 90° in the numerical order shown above.

(e) Check that the painted mark is now at a 90° angle to the front.

(f) Check that the crankshaft turns smoothly.

6. CHECK CRANKSHAFT THRUST CLEARANCE

(See step 5 in cylinder block disassembly)

Front Mark

(Cavity)

Front

P02366 R7696

202418

7. INSTALL PISTON AND CONNECTING ROD ASSEMBLIES

Using a piston ring compressor, push the correctly numbered piston and connecting rod assemblies into each cylinder with the front mark of the piston facing forward.

P04479

8. INSTALL CONNECTING ROD CAPS

A. Place connecting rod cap on connecting rod

(a) Match the numbered connecting rod cap with the connecting rod.

(b) Install the connecting rod cap with by aligning the dowel pin to the corrosponding hole.

B. Install connecting rod cap bolts

HINT:

• The connecting rod cap bolts are tightened in 2 progressive steps (steps (b) and (d)).

• If any of the connecting rod bolts break or deform, replace them.

(a) Apply a light coat of engine oil on the threads and under the heads of the connecting rod cap bolts.

(b) At first, install and alternately tighten the bolts of the connecting rod cap in several passes.

Torque: 29 N·m (300 kgf·cm, 22 ft·lbf)

If any one of the connecting rod cap bolts does not meet the torque specification, replace the cap bolt.

P02426