EG–120

ENGINE – ENGINE MECHANICAL

Front

Painted

Mark

P02419

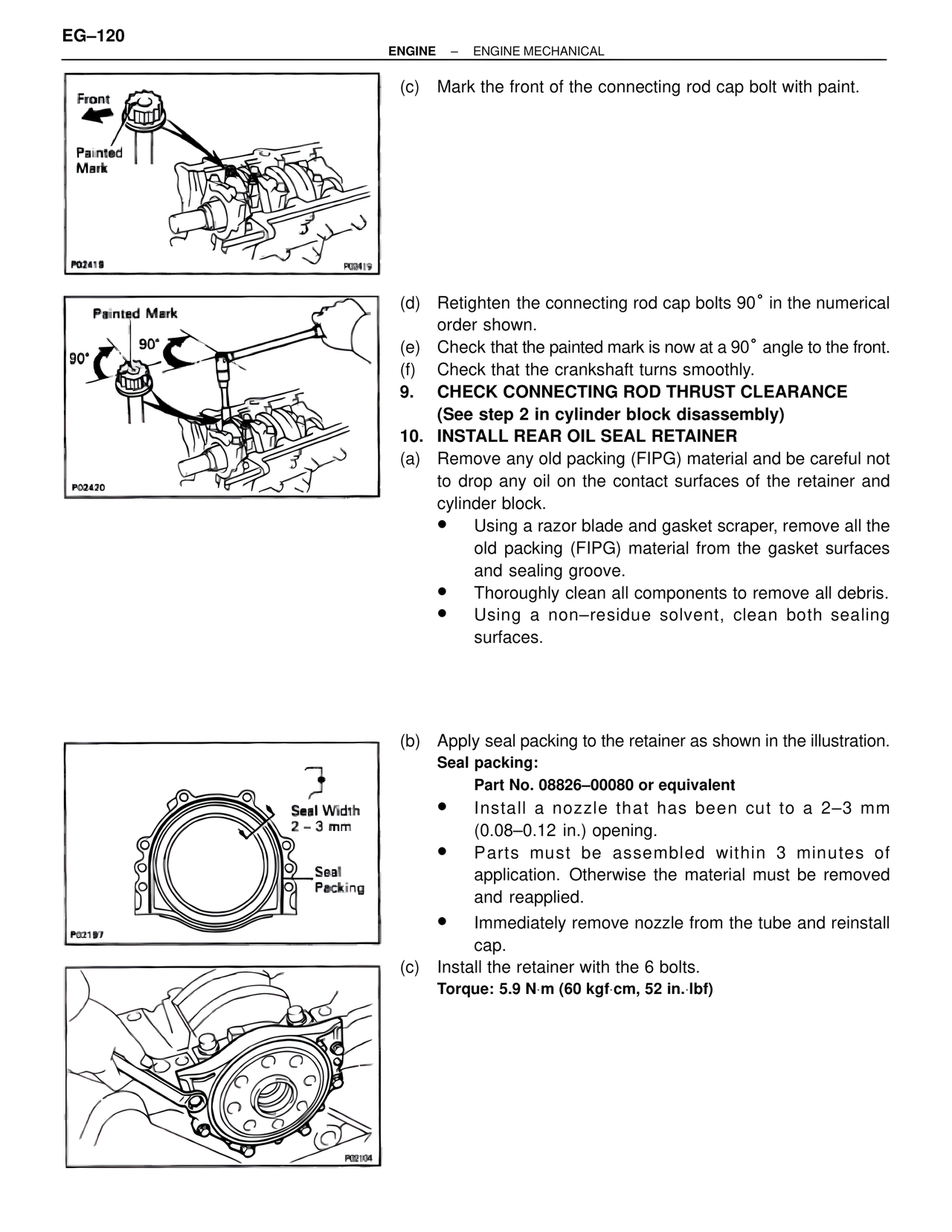

(c) Mark the front of the connecting rod cap bolt with paint.

Painted Mark

90°

90°

P02420

(d) Retighten the connecting rod cap bolts 90° in the numerical order shown.

(e) Check that the painted mark is now at a 90° angle to the front.

(f) Check that the crankshaft turns smoothly.

9. CHECK CONNECTING ROD THRUST CLEARANCE

(See step 2 in cylinder block disassembly)

10. INSTALL REAR OIL SEAL RETAINER

(a) Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the retainer and cylinder block.

• Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing groove.

• Thoroughly clean all components to remove all debris.

• Using a non–residue solvent, clean both sealing surfaces.

Seal Width

2 – 3 mm

Seal

Packing

P02197

(b) Apply seal packing to the retainer as shown in the illustration.

Seal packing:

Part No. 08826–00080 or equivalent

• Install a nozzle that has been cut to a 2–3 mm (0.08–0.12 in.) opening.

• Parts must be assembled within 3 minutes of application. Otherwise the material must be removed and reapplied.

• Immediately remove nozzle from the tube and reinstall cap.

P02104

(c) Install the retainer with the 6 bolts.

Torque: 5.9 N·m (60 kgf·cm, 52 in.·lbf)