EG–57

ENGINE – ENGINE MECHANICAL

10. INSPECT CAMSHAFTS AND BEARINGS

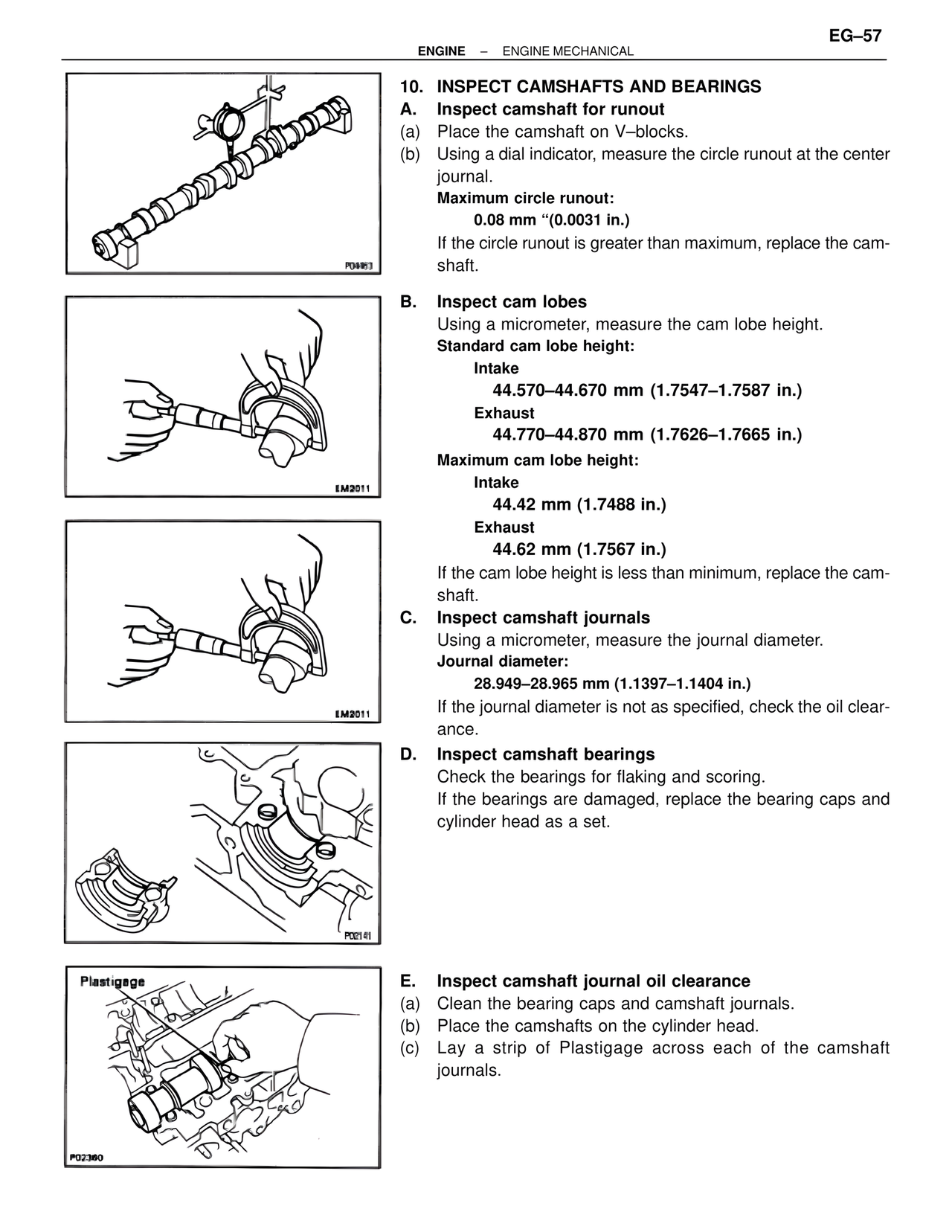

A. Inspect camshaft for runout

(a) Place the camshaft on V–blocks.

(b) Using a dial indicator, measure the circle runout at the center journal.

Maximum circle runout:

0.08 mm "(0.0031 in.)

If the circle runout is greater than maximum, replace the camshaft.

B. Inspect cam lobes

Using a micrometer, measure the cam lobe height.

Standard cam lobe height:

Intake

44.570–44.670 mm (1.7547–1.7587 in.)

Exhaust

44.770–44.870 mm (1.7626–1.7665 in.)

Maximum cam lobe height:

Intake

44.42 mm (1.7488 in.)

Exhaust

44.62 mm (1.7567 in.)

If the cam lobe height is less than minimum, replace the camshaft.

C. Inspect camshaft journals

Using a micrometer, measure the journal diameter.

Journal diameter:

28.949–28.965 mm (1.1397–1.1404 in.)

If the journal diameter is not as specified, check the oil clearance.

D. Inspect camshaft bearings

Check the bearings for flaking and scoring.

If the bearings are damaged, replace the bearing caps and cylinder head as a set.

Plastigage

E. Inspect camshaft journal oil clearance

(a) Clean the bearing caps and camshaft journals.

(b) Place the camshafts on the cylinder head.

(c) Lay a strip of Plastigage across each of the camshaft journals.

P04953

EM2011

EM2011

P02141

P02360