LU-16

LUBRICATION - OIL PUMP

LU050-02

INSTALLATION

1. INSTALL OIL PUMP

(a) Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the oil pump and cylinder block.

• Using a razor blade gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing groove.

• Thoroughly clean all components to remove all the debris.

• Using a non-residue solvent, clean both sealing surfaces.

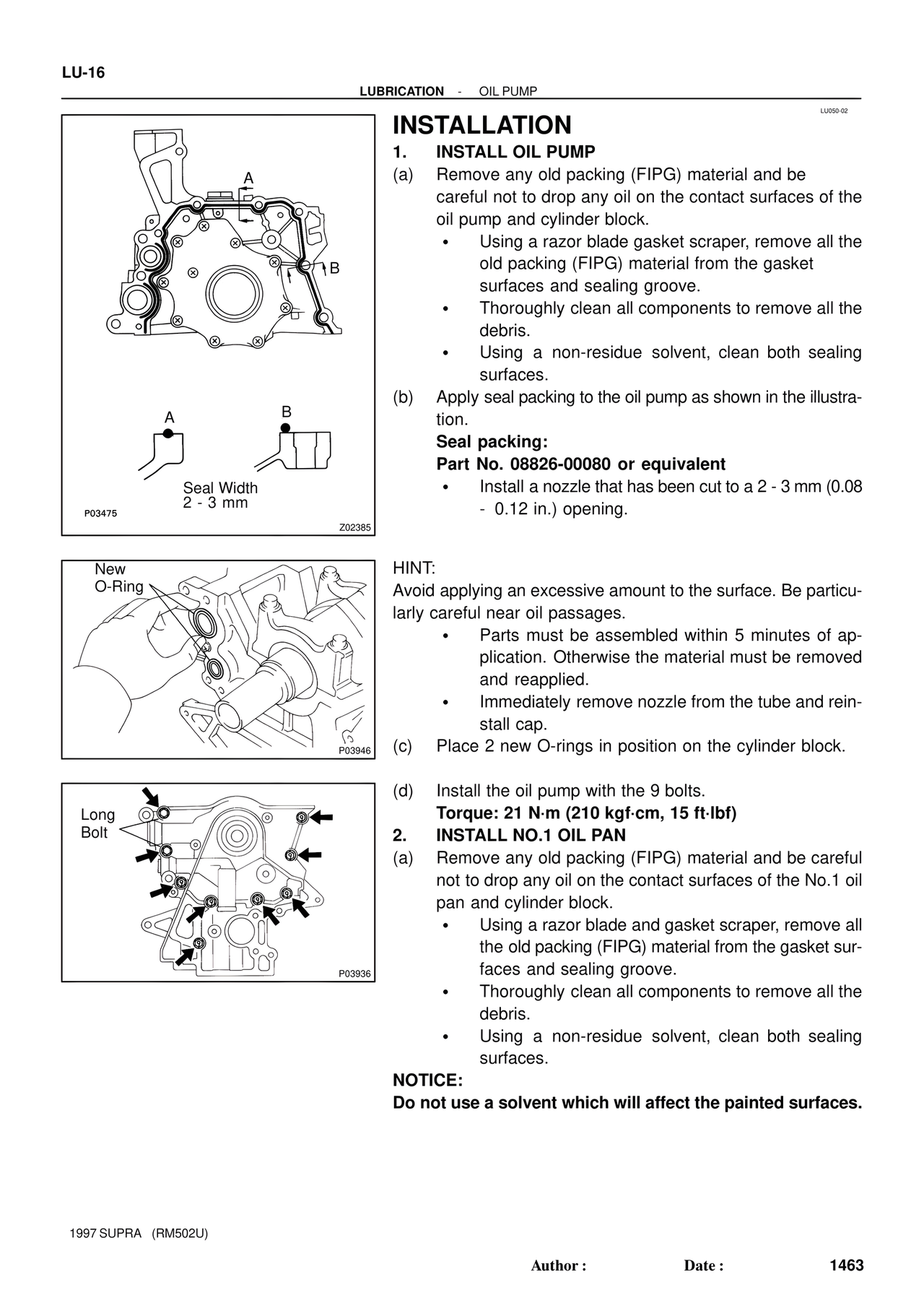

(b) Apply seal packing to the oil pump as shown in the illustration.

Seal packing:

Part No. 08826-00080 or equivalent

• Install a nozzle that has been cut to a 2 - 3 mm (0.08 - 0.12 in.) opening.

A

B

Seal Width

2 - 3 mm

P03475

Z02385

New

O-Ring

P03946

Long

Bolt

P03936

HINT:

Avoid applying an excessive amount to the surface. Be particularly careful near oil passages.

• Parts must be assembled within 5 minutes of application. Otherwise the material must be removed and reapplied.

• Immediately remove nozzle from the tube and reinstall cap.

(c) Place 2 new O-rings in position on the cylinder block.

(d) Install the oil pump with the 9 bolts.

Torque: 21 N·m (210 kgf·cm, 15 ft·lbf)

2. INSTALL NO.1 OIL PAN

(a) Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the No.1 oil pan and cylinder block.

• Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing groove.

• Thoroughly clean all components to remove all the debris.

• Using a non-residue solvent, clean both sealing surfaces.

NOTICE:

Do not use a solvent which will affect the painted surfaces.

1997 SUPRA (RM502U)

Author : Date : 1463