MA–9

MAINTENANCE – MAINTENANCE OPERATIONS

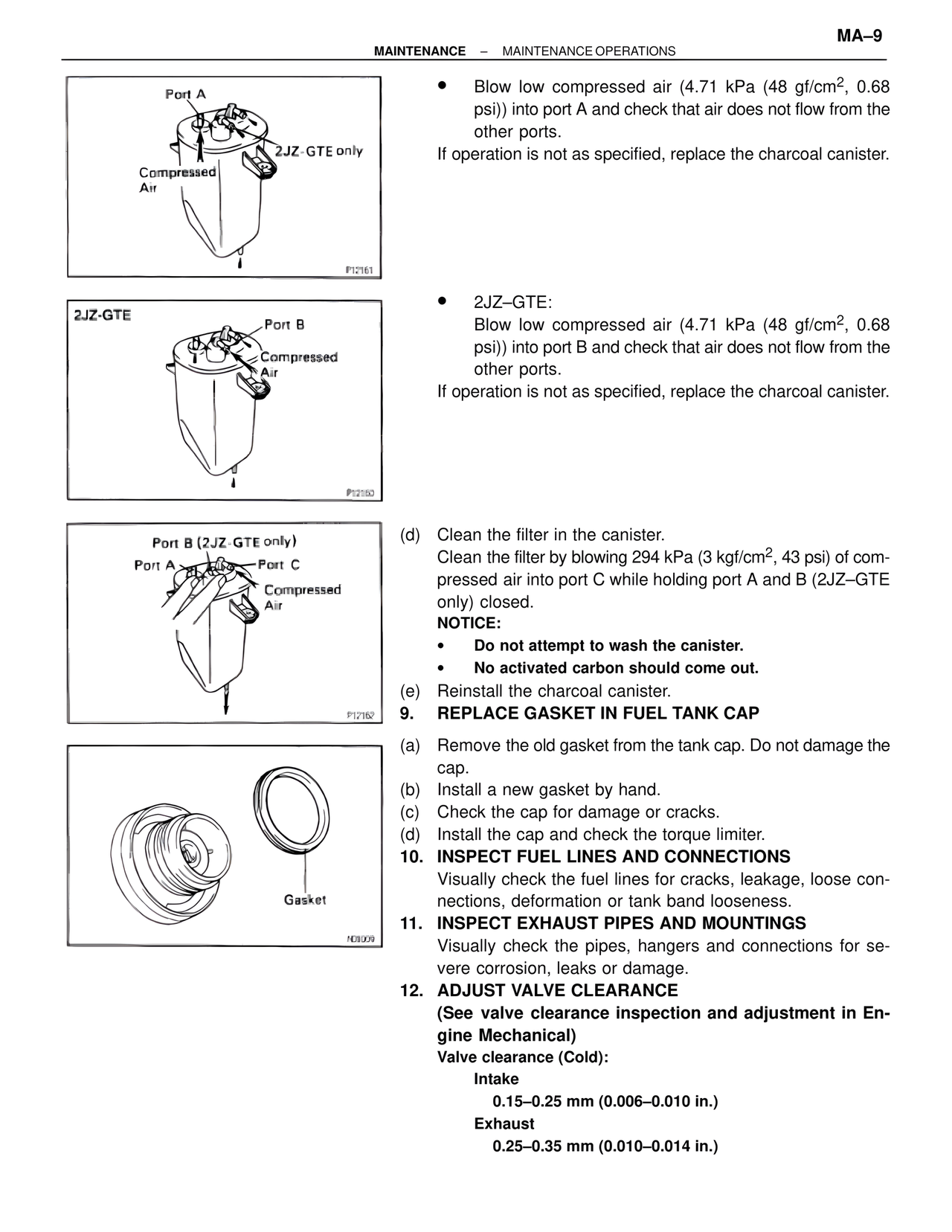

Port A

2JZ-GTE only

Compressed

Air

P12161

• Blow low compressed air (4.71 kPa (48 gf/cm2, 0.68 psi)) into port A and check that air does not flow from the other ports.

If operation is not as specified, replace the charcoal canister.

2JZ-GTE

Port B

Compressed

Air

P12155

• 2JZ–GTE:

Blow low compressed air (4.71 kPa (48 gf/cm2, 0.68 psi)) into port B and check that air does not flow from the other ports.

If operation is not as specified, replace the charcoal canister.

Port B (2JZ-GTE only)

Port A

Port C

Compressed

Air

P12162

(d) Clean the filter in the canister.

Clean the filter by blowing 294 kPa (3 kgf/cm2, 43 psi) of compressed air into port C while holding port A and B (2JZ–GTE only) closed.

NOTICE:

• Do not attempt to wash the canister.

• No activated carbon should come out.

(e) Reinstall the charcoal canister.

9. REPLACE GASKET IN FUEL TANK CAP

Gasket

N08009

(a) Remove the old gasket from the tank cap. Do not damage the cap.

(b) Install a new gasket by hand.

(c) Check the cap for damage or cracks.

(d) Install the cap and check the torque limiter.

10. INSPECT FUEL LINES AND CONNECTIONS

Visually check the fuel lines for cracks, leakage, loose connections, deformation or tank band looseness.

11. INSPECT EXHAUST PIPES AND MOUNTINGS

Visually check the pipes, hangers and connections for severe corrosion, leaks or damage.

12. ADJUST VALVE CLEARANCE

(See valve clearance inspection and adjustment in Engine Mechanical)

Valve clearance (Cold):

Intake

0.15–0.25 mm (0.006–0.010 in.)

Exhaust

0.25–0.35 mm (0.010–0.014 in.)